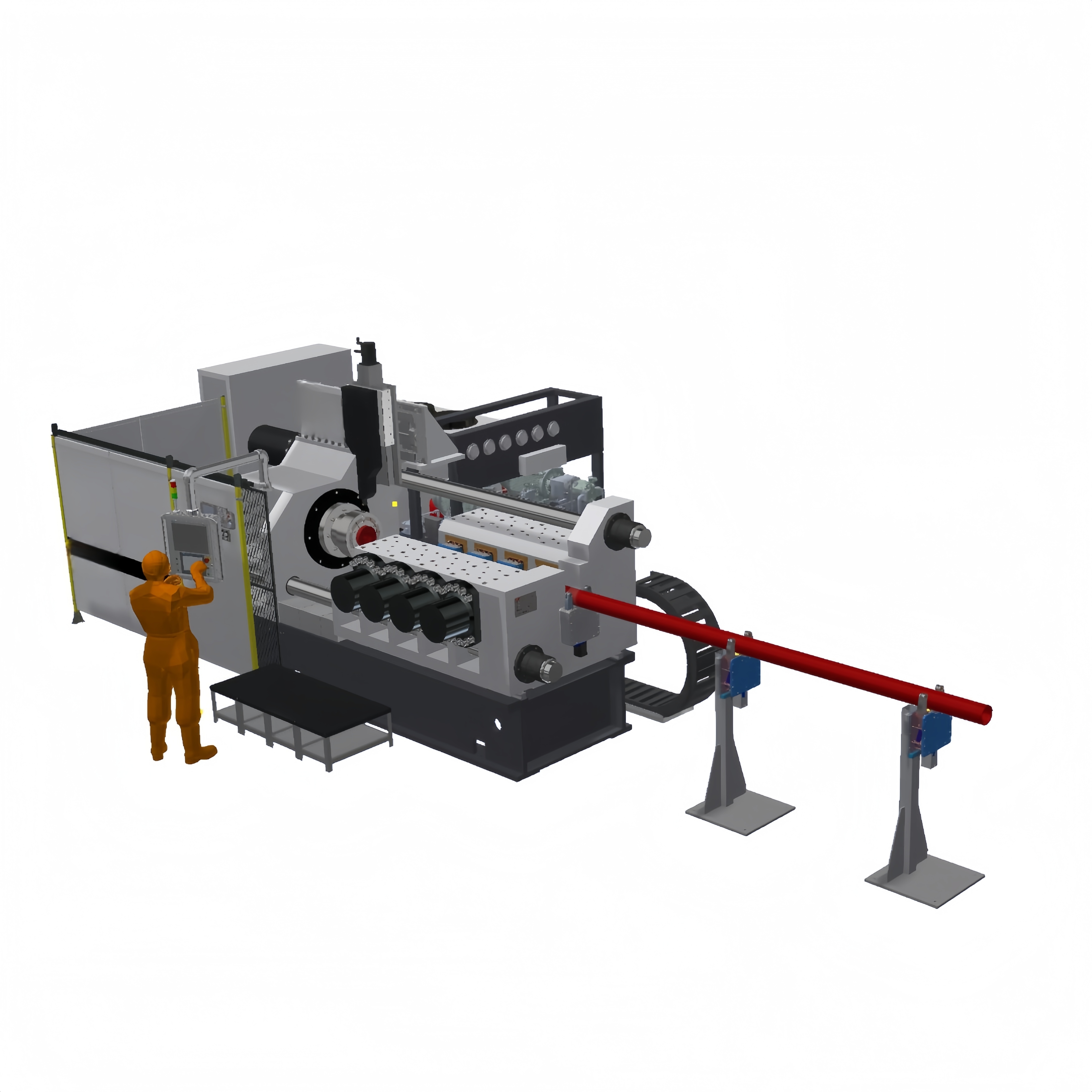

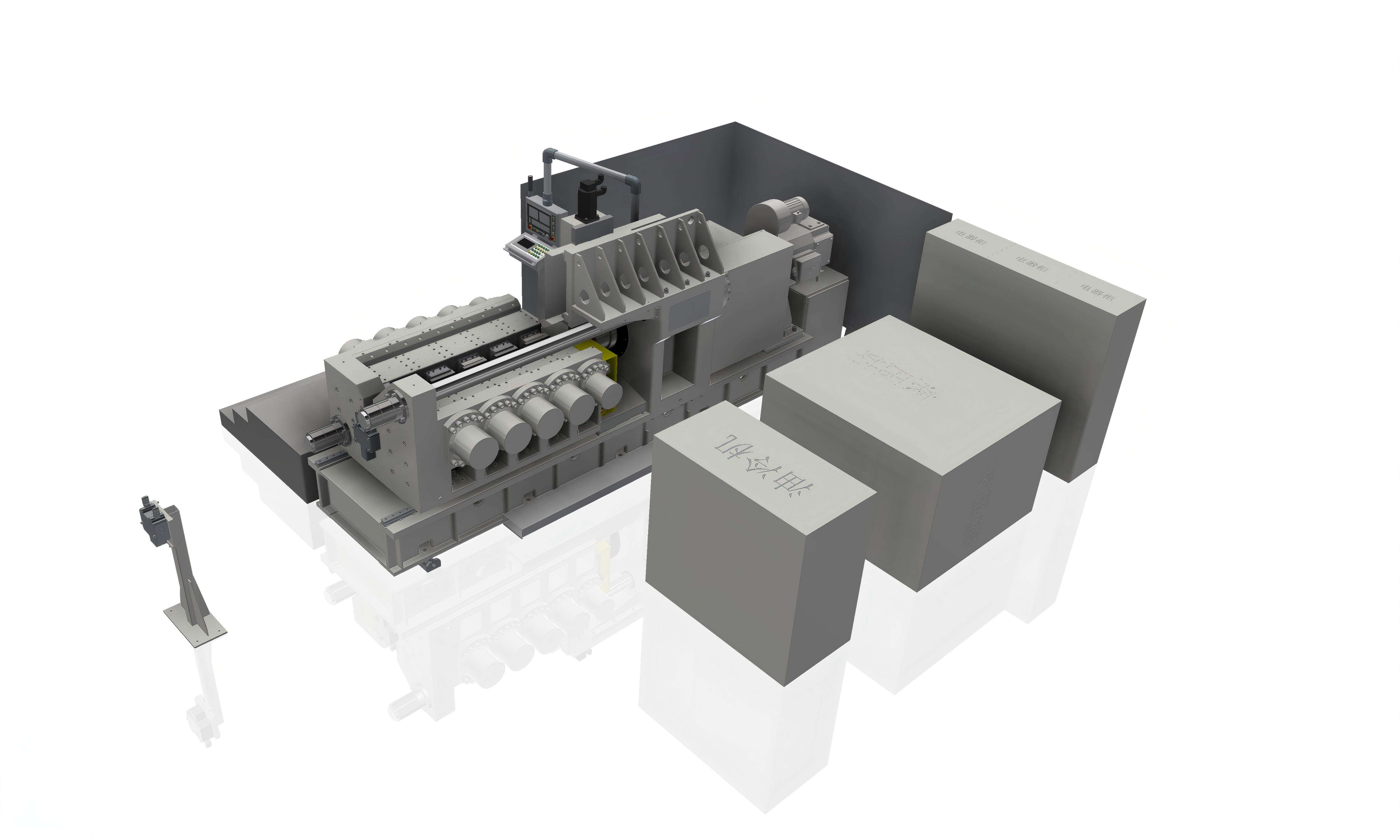

Drill pipe friction welding machines are specialized equipment that utilize the solid state friction welding process to join drill pipes and drill rods, a critical application in industries like oil and gas exploration, mining, and geothermal drilling. Unlike fusion welding, this process generates heat through controlled rotational friction between the two workpieces, creating a bond without melting the base materials. This results in several key advantages: enhanced joint strength and consistency, as the absence of molten metal eliminates issues like porosity or cracking; a minimized heat affected zone (HAZ), preserving the mechanical properties of the drill pipe material, which is vital for withstanding high pressures, torsional forces, and abrasive drilling environments; and the ability to join dissimilar metals, allowing manufacturers to combine high strength steel with corrosion resistant alloys for optimized performance. Additionally, these machines reduce material waste by eliminating the need for filler metals or fluxes, lowering production costs and environmental impact. WondersunM, with over 25 years of industrial expertise, designs drill pipe friction welding machines with strict quality control throughout the manufacturing process. Their equipment is tailored to handle varying pipe diameters and material combinations, supported by a professional technical team that offers customization for specific drilling requirements. Exported to over 100 countries, these machines come with comprehensive service, including on site installation, commissioning, and training, ensuring reliability for global clients in demanding industries.