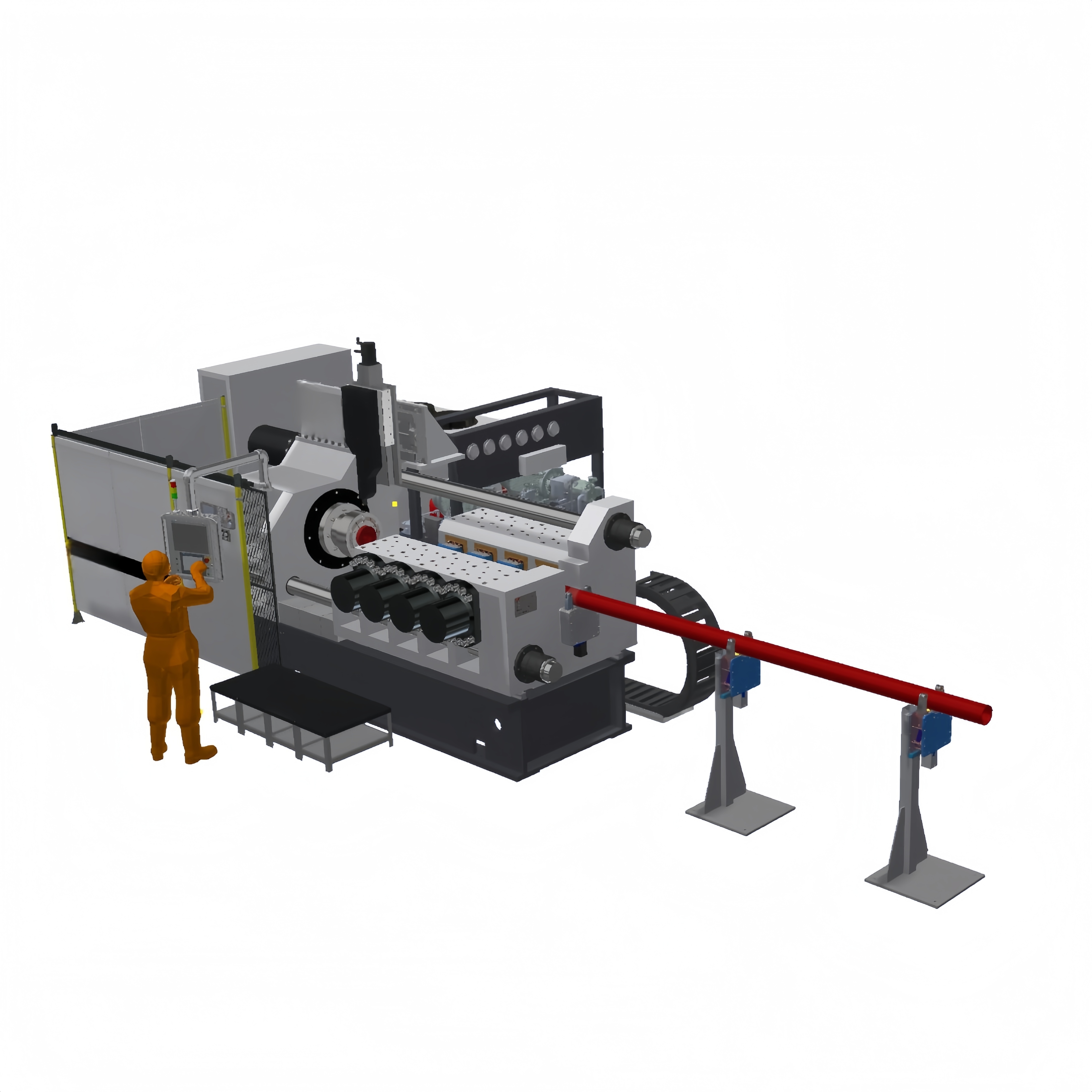

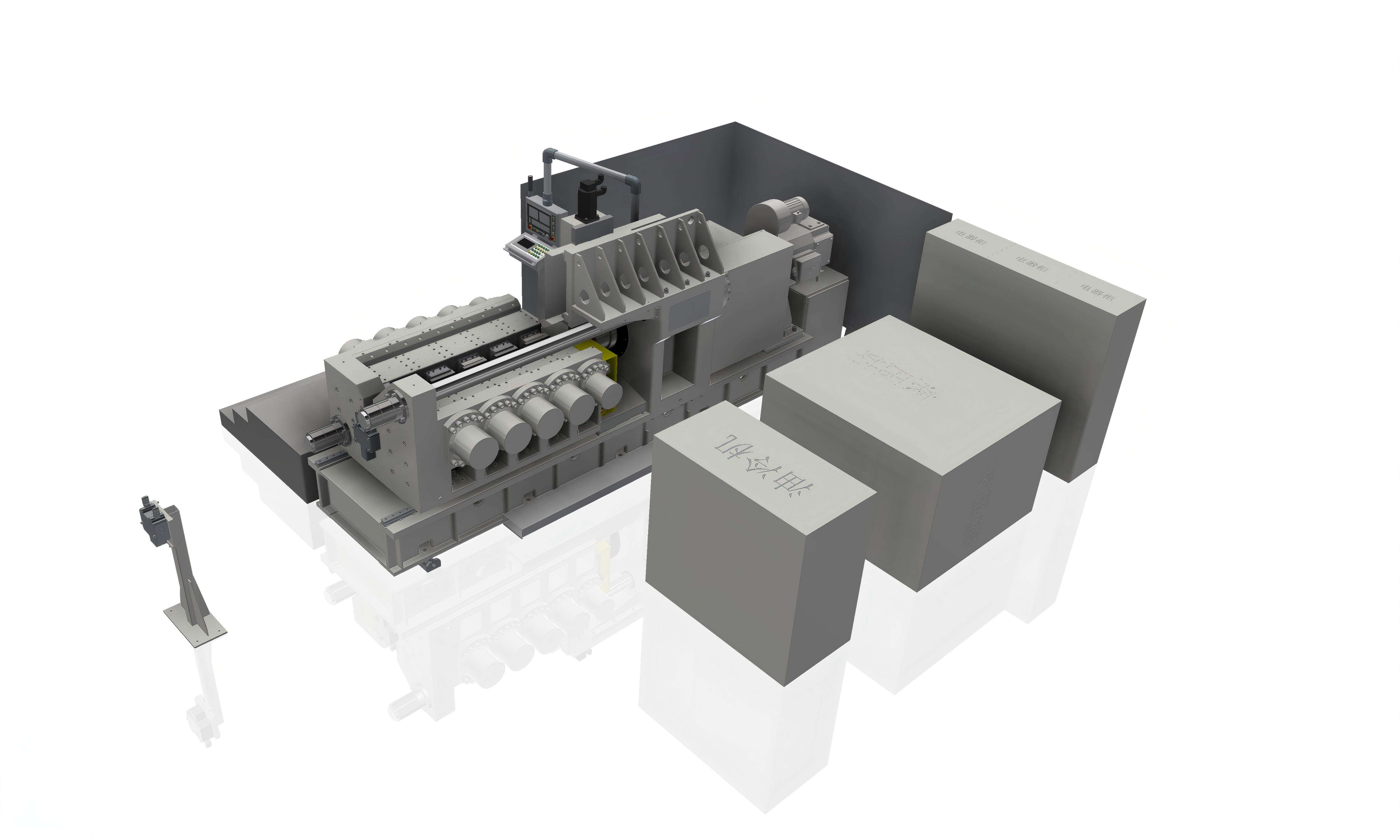

Through the use of flywheel energy storage, this machine performs short, but high power (500kW) welds by transferring rotational inertia to workpieces. The flywheel mass is within the range of 5 to 50 kgꞏm², providing fine control of heat input, enabling the welding of materials such as tungsten alloys. Typical applications include oil drill pipe connections and aerospace engine components, where its rapid cooling process reduces grain growth while ensuring microstructural homogeneity.