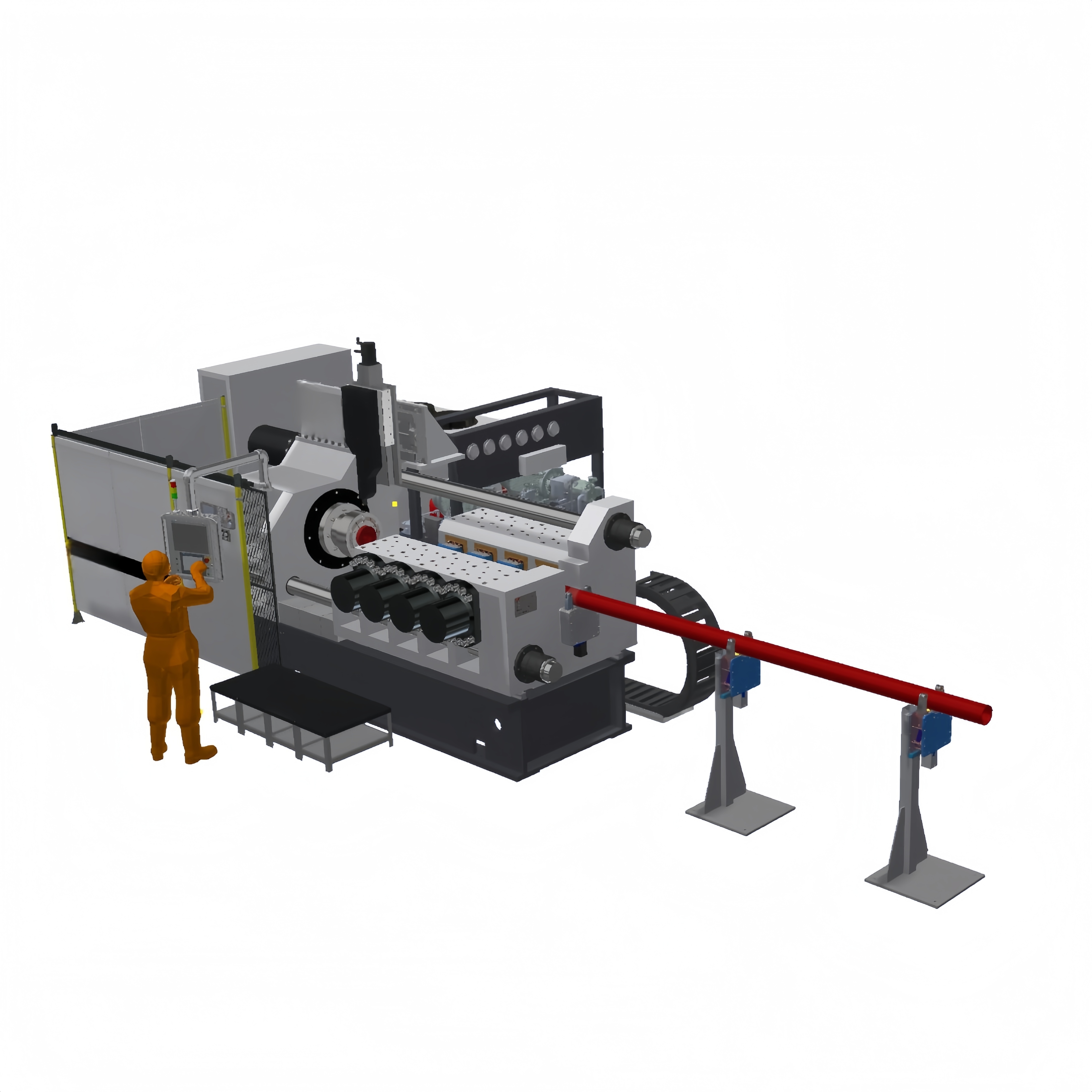

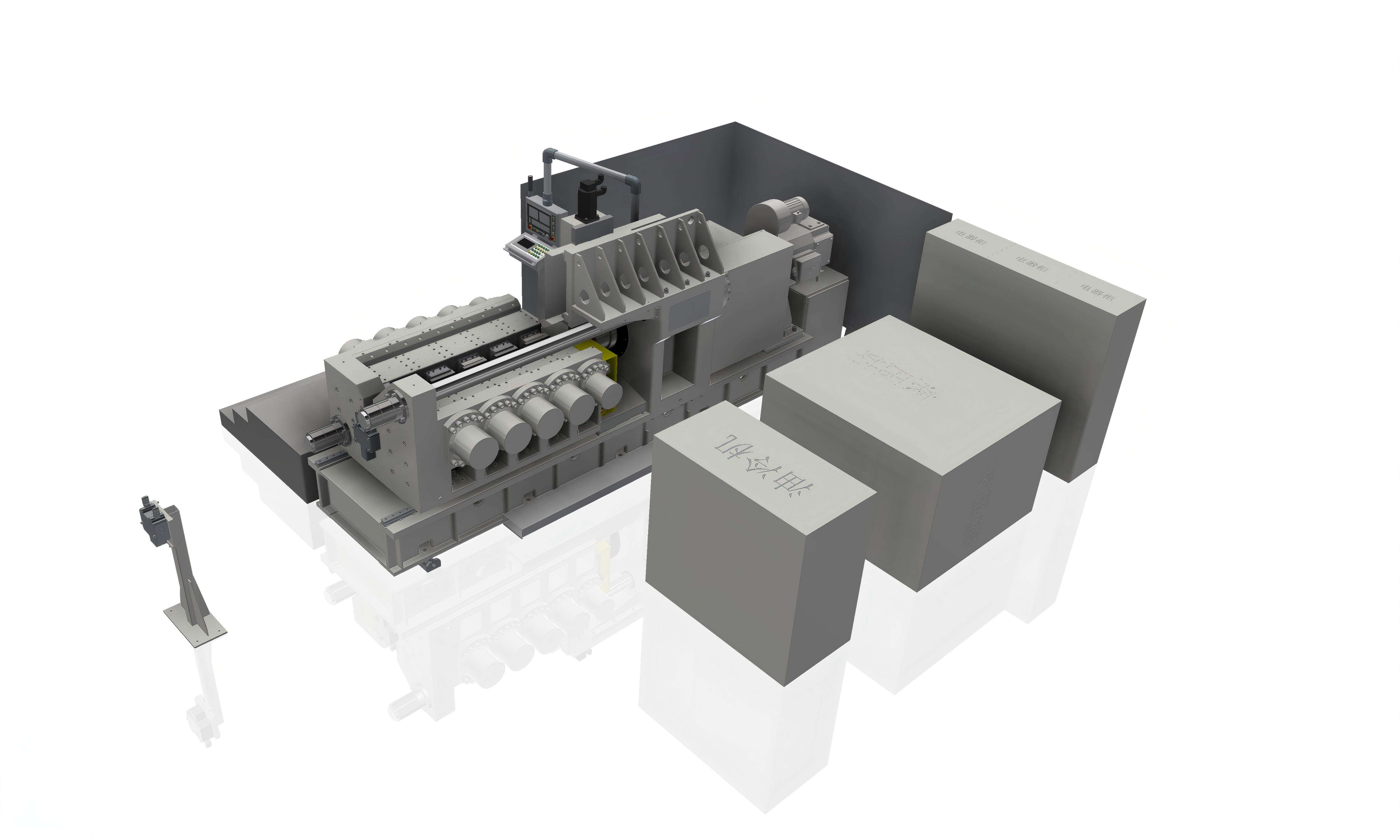

เครื่องเชื่อมด้วยแรงเสียดทานท่อเจาะเป็นอุปกรณ์เฉพาะทางที่ใช้กระบวนการเชื่อมด้วยแรงเสียดทานแบบสถานะแข็ง เพื่อเชื่อมต่อท่อเจาะและแท่งเจาะ ซึ่งเป็นการประยุกต์ใช้งานที่สำคัญในอุตสาหกรรมต่างๆ เช่น การสำรวจและขุดเจาะน้ำมันและก๊าซธรรมชาติ อุตสาหกรรมเหมืองแร่ และการขุดเจาะพลังงานความร้อนใต้พิภพ ในทางตรงกันข้ามกับการเชื่อมแบบหลอมละลาย กระบวนการนี้สร้างความร้อนผ่านแรงเสียดทานจากการหมุนที่ควบคุมได้ระหว่างชิ้นงานทั้งสอง ทำให้เกิดการเชื่อมต่อโดยไม่หลอมละลายวัสดุฐาน ซึ่งนำมาซึ่งข้อดีที่สำคัญหลายประการ ได้แก่ ความแข็งแรงและความสม่ำเสมอของรอยต่อที่เพิ่มขึ้น เนื่องจากไม่มีโลหะหลอมเหลว จึงหลีกเลี่ยงปัญหาอย่างเช่น รูพรุนหรือการแตกร้าว ขนาดของพื้นที่ที่ได้รับผลกระทบจากความร้อน (HAZ) มีขนาดเล็กลง ช่วยรักษาคุณสมบัติทางกลของวัสดุท่อเจาะไว้ ซึ่งมีความสำคัญอย่างมากในการรับแรงดันสูง แรงบิด และสภาพแวดล้อมการเจาะที่มีการกัดกร่อน และความสามารถในการเชื่อมโลหะที่ต่างชนิดกัน ทำให้ผู้ผลิตสามารถนำเหล็กกล้าความแข็งแรงสูงมาผสมผสานกับโลหะผสมที่ทนต่อการกัดกร่อน เพื่อประสิทธิภาพที่เหมาะสม นอกจากนี้ เครื่องจักรเหล่านี้ยังช่วยลดของเสียจากวัสดุโดยไม่ต้องใช้โลหะเติมหรือสารประสาน ลดต้นทุนการผลิตและผลกระทบต่อสิ่งแวดล้อม WondersunM ซึ่งมีความเชี่ยวชาญในอุตสาหกรรมมานานกว่า 25 ปี ออกแบบเครื่องเชื่อมด้วยแรงเสียดทานท่อเจาะภายใต้การควบคุมคุณภาพที่เข้มงวดตลอดกระบวนการผลิต อุปกรณ์ของบริษัทถูกออกแบบมาให้รองรับท่อที่มีเส้นผ่านศูนย์กลางต่างกันรวมถึงวัสดุที่มีคุณสมบัติแตกต่างกัน โดยมีทีมเทคนิคมืออาชีพคอยสนับสนุนและให้บริการปรับแต่งเครื่องตามความต้องการเฉพาะของลูกค้า นอกจากนี้ เครื่องจักรยังได้รับการส่งออกไปยังกว่า 100 ประเทศ พร้อมบริการครบวงจร ได้แก่ การติดตั้ง ทดสอบเดินเครื่อง และฝึกอบรมในสถานที่จริง เพื่อให้มั่นใจได้ถึงความน่าเชื่อถือสำหรับลูกค้าทั่วโลกในอุตสาหกรรมที่มีความต้องการสูง