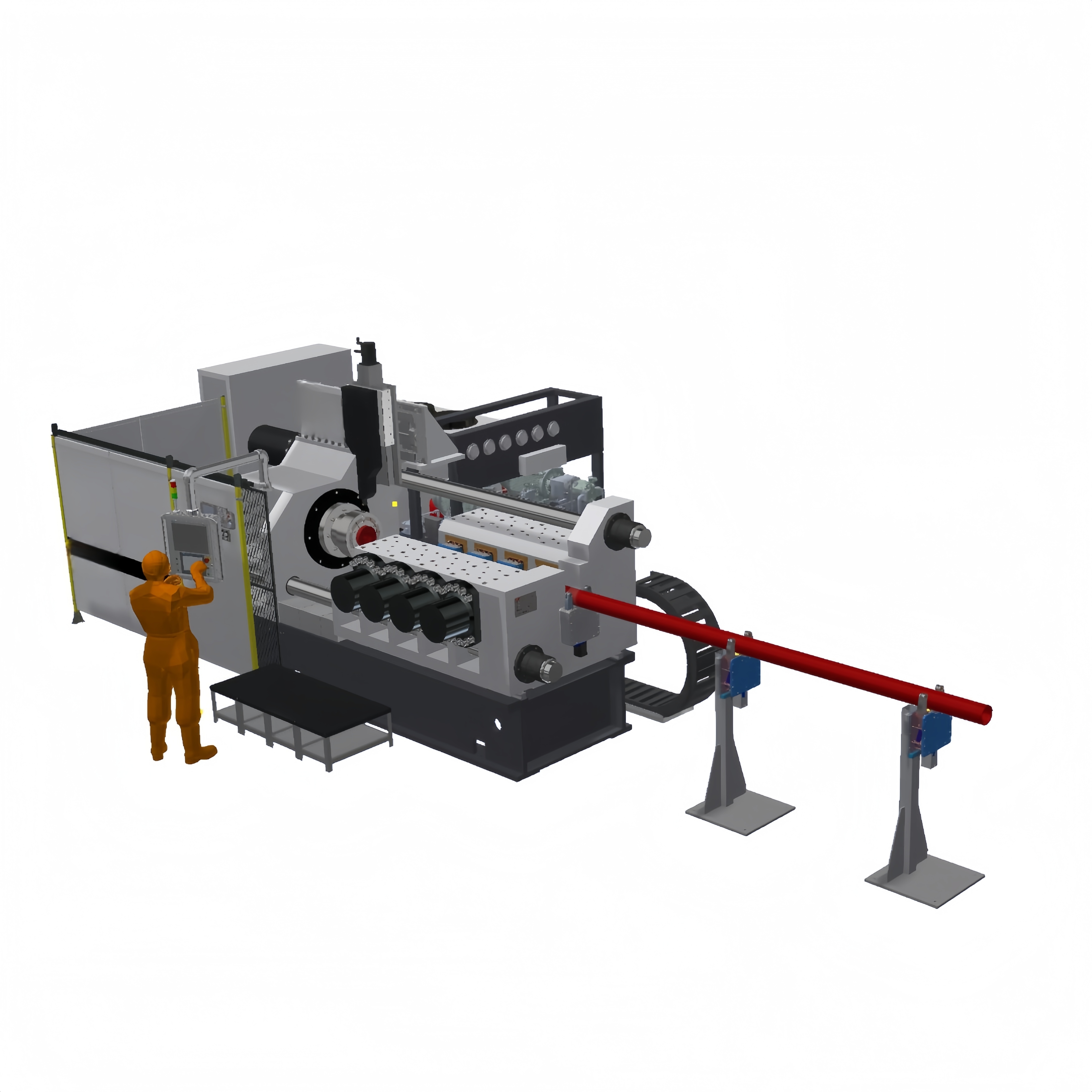

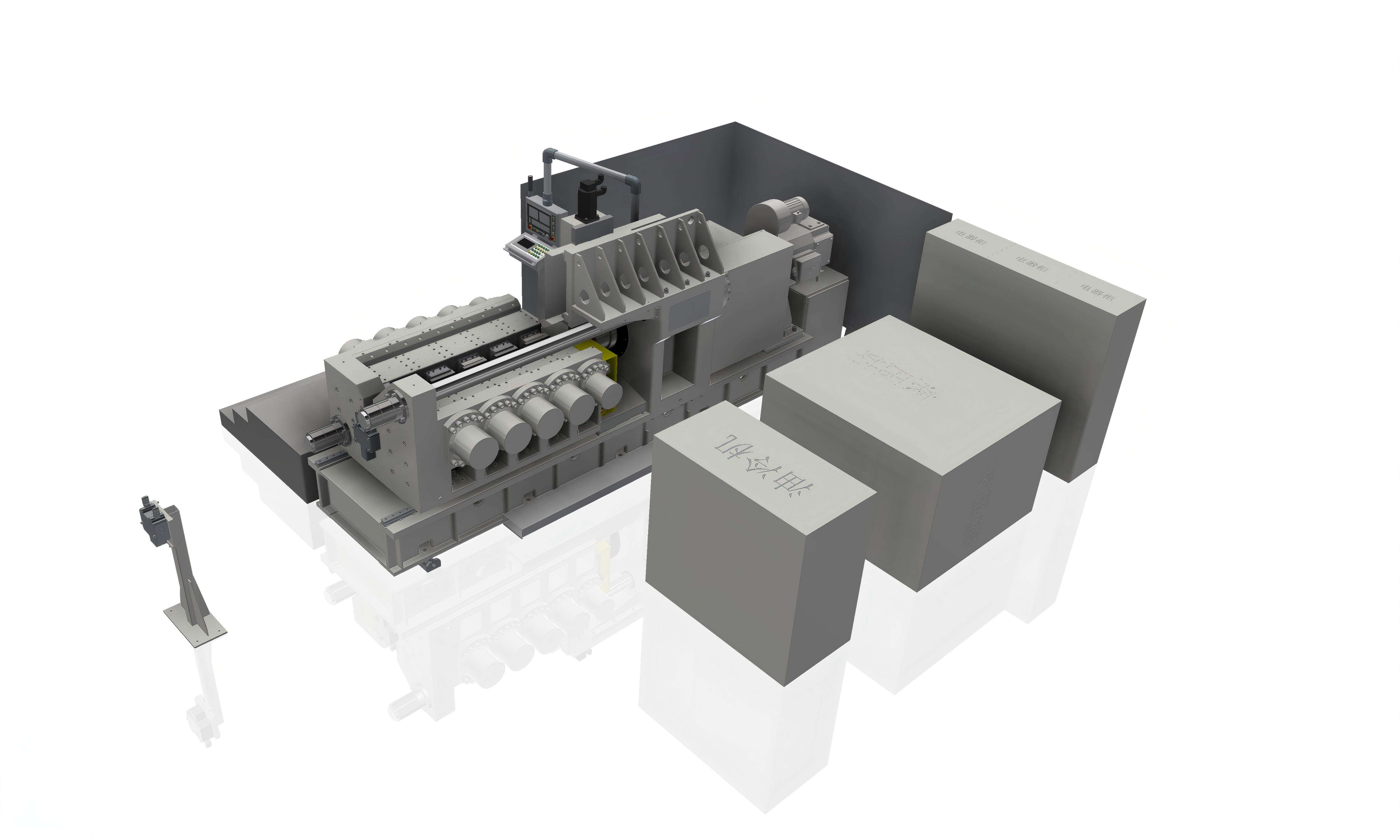

Stainless steel friction welding machines are engineered to address the unique challenges of joining stainless steel, a material valued for its corrosion resistance, strength, and hygiene properties but prone to issues like oxidation and embrittlement when welded using traditional fusion methods. By using friction generated heat (instead of open flames or arcs), these machines create solid state bonds that minimize heat input, preserving the chromium oxide layer critical for stainless steel’s corrosion resistance. The process avoids molten metal, reducing the risk of 晶间腐蚀 (intergranular corrosion) and maintaining the material’s mechanical strength—essential for applications in food processing, medical equipment, chemical storage, and marine engineering. These machines excel at joining different grades of stainless steel (e.g., 304, 316) and even dissimilar metals like stainless steel and carbon steel, expanding design flexibility. WondersunM’s stainless steel friction welding machines feature precise torque and pressure control to accommodate the material’s high thermal conductivity and tensile strength. Backed by a team experienced in international trade, they offer customization for part sizes and production volumes, ensuring compliance with global standards (e.g., ASTM, ISO). With services including on site support, these machines provide reliable, high quality joins, making them a trusted choice for industries where material integrity is non negotiable.