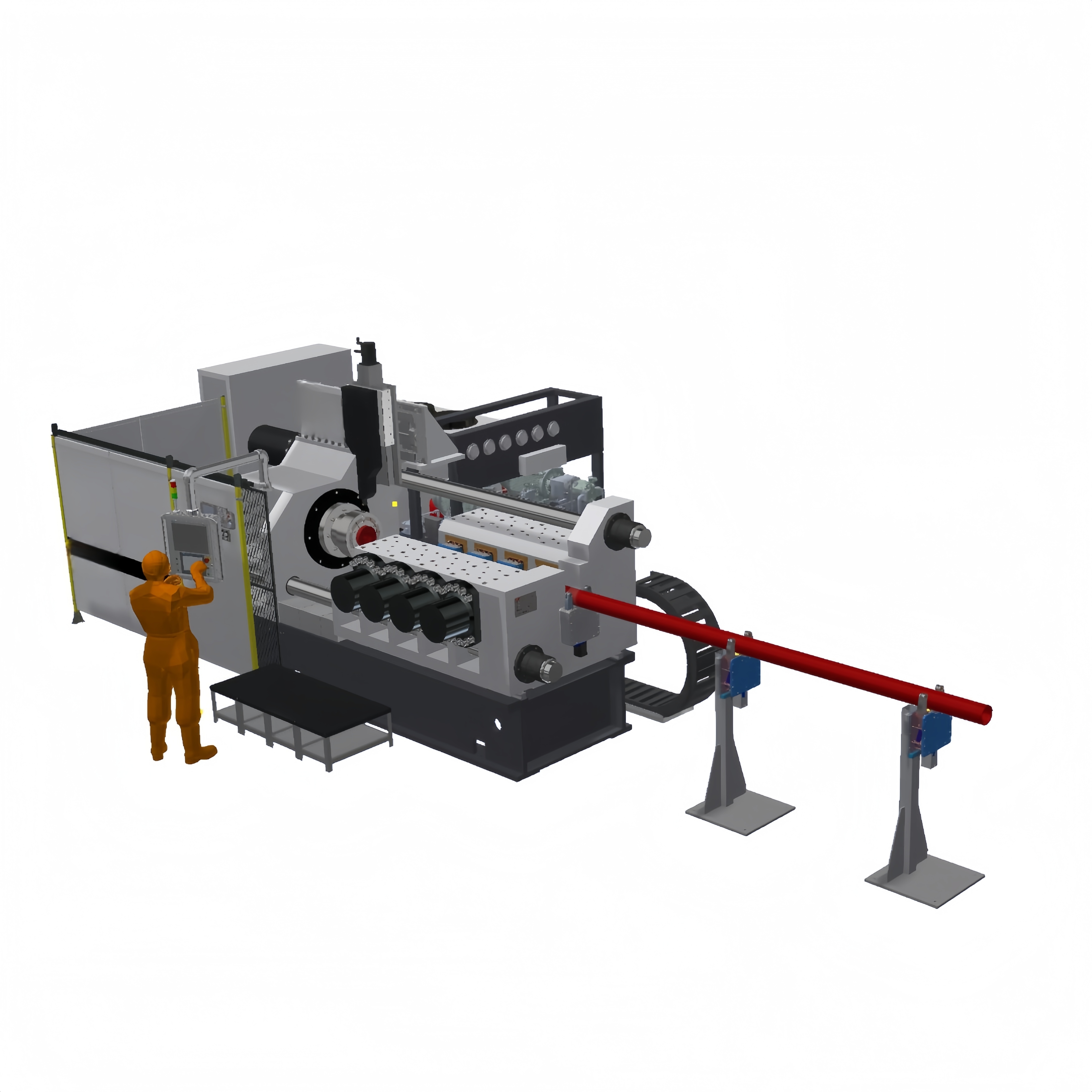

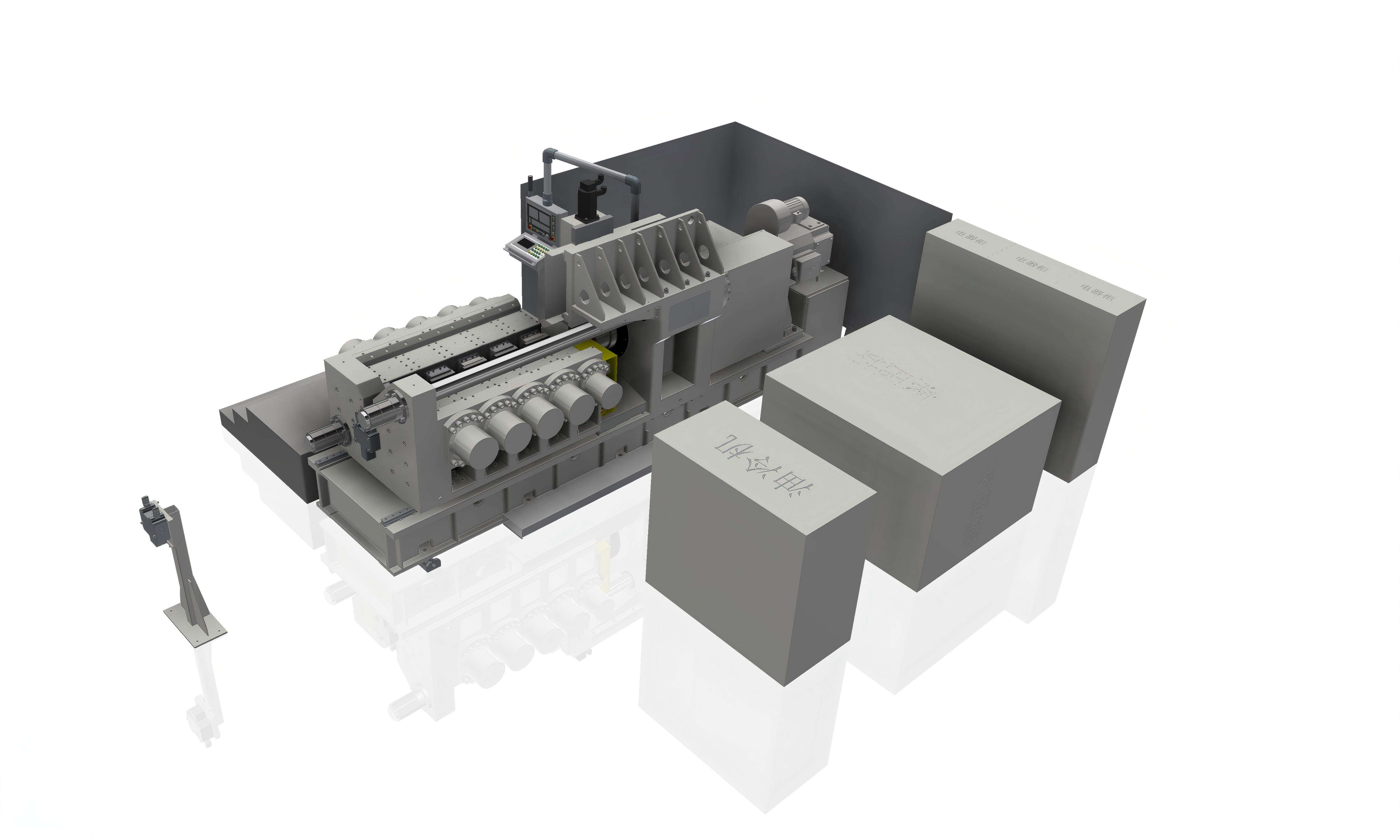

Burmashlarni ishqalanish bilan payvandlash mashinalari — bu neft va gaz so'rish, qazish, geotermal burilish kabi sohalarda muhim dasturlarga ega bo'lgan burmashlar va burilish sterjenlarini birlashtirish uchun qattiq holatdagi ishqalanish payvandlash jarayonidan foydalanadigan maxsus jihozlardir. Qayta ishlash payvandlashidan farqli o'laroq, ushbu jarayon ikkita ishchi qismlar o'rtasidagi nazorat qilinadigan aylanma ishqalanish orqali issiqlik hosil qiladi va asosiy materiallarni eritmasdan birikma hosil qiladi. Bu esa bir nechta muhim afzalliklarga olib keladi: poroznost yoki kuzatish kabi muammolarni bartaraf etish orqali birikma mustahkamligi va barqarorligini oshirish; ishqalanish ta'sir zonasini (HAZ) minimal darajada saqlab qolish orqali burmash materialining mexanik xususiyatlarini saqlash, bu esa yuqori bosim, burilish kuchlari va yeyuvchi muhitga chidash uchun muhim ahamiyatga ega; turli metallarni birlashtirish imkoniyati, bu esa ishlab chiqaruvchilarga yuqori mustahkamlikli po'latni korroziyaga chidamli qotishmalar bilan birlashtirish orqali optimallashtirilgan ishlashni ta'minlaydi. Shuningdek, ushbu mashinalar to'ldiruvchi metallar yoki fluslarning keraksizligi tufayli materialni tejaydi, ishlab chiqarish xarajatlarini va atrof-muhitga ta'sirini kamaytiradi. 25 yildan ortiq sanoat tajribasiga ega bo'lgan WondersunM burmashlarni ishqalanish bilan payvandlash mashinalarini ishlab chiqarish jarayonida qat'iy sifat nazorati bilan loyihalaydi. Ushbu jihozlar turli quvur diametrlari va materiallar kombinatsiyasini qayta ishlashga moslashtirilgan bo'lib, mutaxassislardan tashkil topgan professional texnik jamoaning ma'lum burilish talablari uchun moslashtirish xizmati ham qo'llab-quvvatlanadi. 100 dan ortiq mamlakatlarga eksport qilingan ushbu mashinalar, global mijozlar uchun ishonchli ishlashni kafolatlovchi, obyektda o'rnatish, sozlash va o'qitishni o'z ichiga olgan kengaytirilgan xizmat bilan taqdim etiladi.