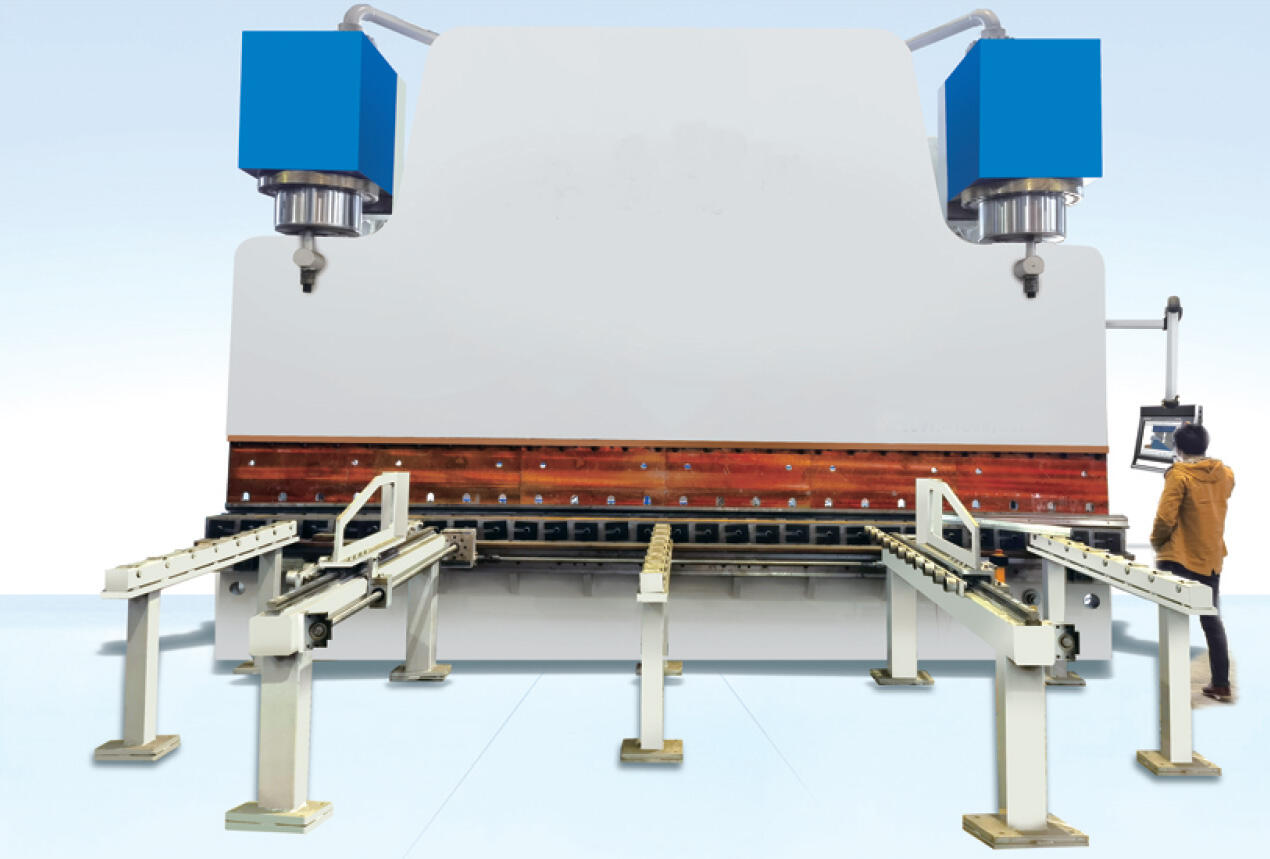

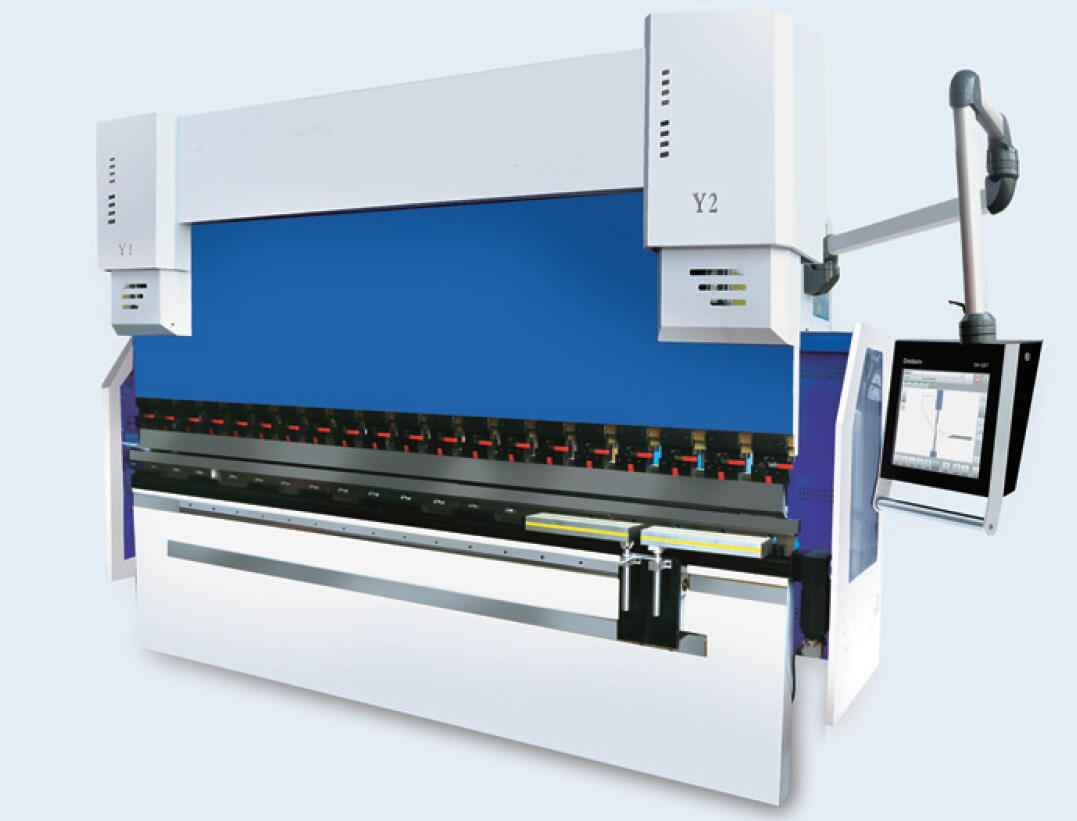

A bending machine is a versatile industrial tool used to deform metal sheets, plates, or profiles into specific angular shapes, curves, or complex geometries, playing a pivotal role in industries ranging from automotive and aerospace to construction and furniture manufacturing. Operating on the principle of applying force to a workpiece placed between a punch (upper tool) and a die (lower tool), bending machines utilize mechanical, hydraulic, pneumatic, or servo electric power to achieve controlled deformation without breaking or fracturing the material. The key parameters governing the bending process include bend angle, bend radius, material thickness, and tensile strength, all of which influence the selection of machine type, tooling, and force requirements. Mechanical bending machines, powered by flywheels and clutches, are ideal for low to medium volume production of simple bends, offering high speed and cost effectiveness for materials like mild steel and aluminum. Hydraulic bending machines, on the other hand, use hydraulic cylinders to deliver consistent force across the workpiece, making them suitable for thick materials (up to 50mm) and complex bends requiring precise force control. Servo electric models, a more modern innovation, combine the accuracy of hydraulic systems with the energy efficiency of electric drives, providing programmable control over speed, force, and position for high precision applications such as aerospace component manufacturing. The tooling—punches and dies—is critical to bending machine performance, with designs tailored to the material and desired shape. V dies are common for angular bends, with varying groove widths to accommodate different material thicknesses, while radius dies produce curved bends with specific radii to prevent material cracking. Modern bending machines often integrate CNC (Computer Numerical Control) systems, allowing operators to program bend sequences, angles, and tool changes, reducing setup time and ensuring repeatability within ±0.1° for critical applications. Safety features such as light curtains, emergency stop buttons, and two hand operation controls are mandatory to protect operators from pinch points and flying debris. In automotive production, bending machines shape chassis components, door frames, and exhaust pipes; in construction, they form structural steel beams and roofing panels; in furniture manufacturing, they create metal frames for chairs and tables. The ability to handle materials from thin gauge sheets (0.1mm) to thick plates (over 100mm) makes bending machines indispensable in metalworking. Advanced models may include features like backgauges for precise workpiece positioning, crowning systems to compensate for tool deflection in long workpieces, and simulation software to predict springback—the tendency of material to return to its original shape after bending—allowing operators to adjust parameters pre emptively. As sustainability becomes a priority, energy efficient bending machines with regenerative drives are gaining popularity, reducing power consumption while maintaining performance. Compliance with international standards such as ISO 12100 (safety of machinery) and EN 12625 (bending machines for sheet metal) ensures that these tools meet global safety and performance criteria, facilitating their use in diverse cultural and industrial contexts.