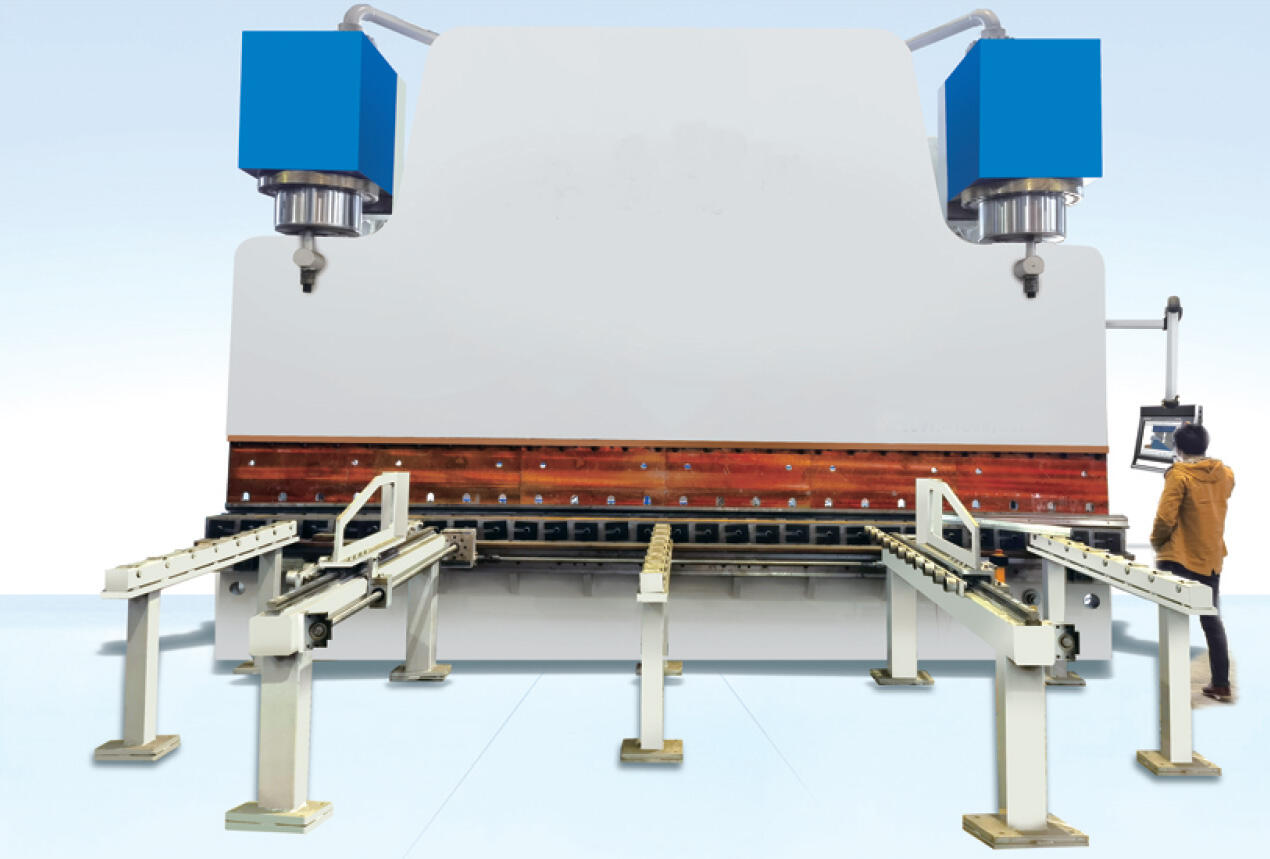

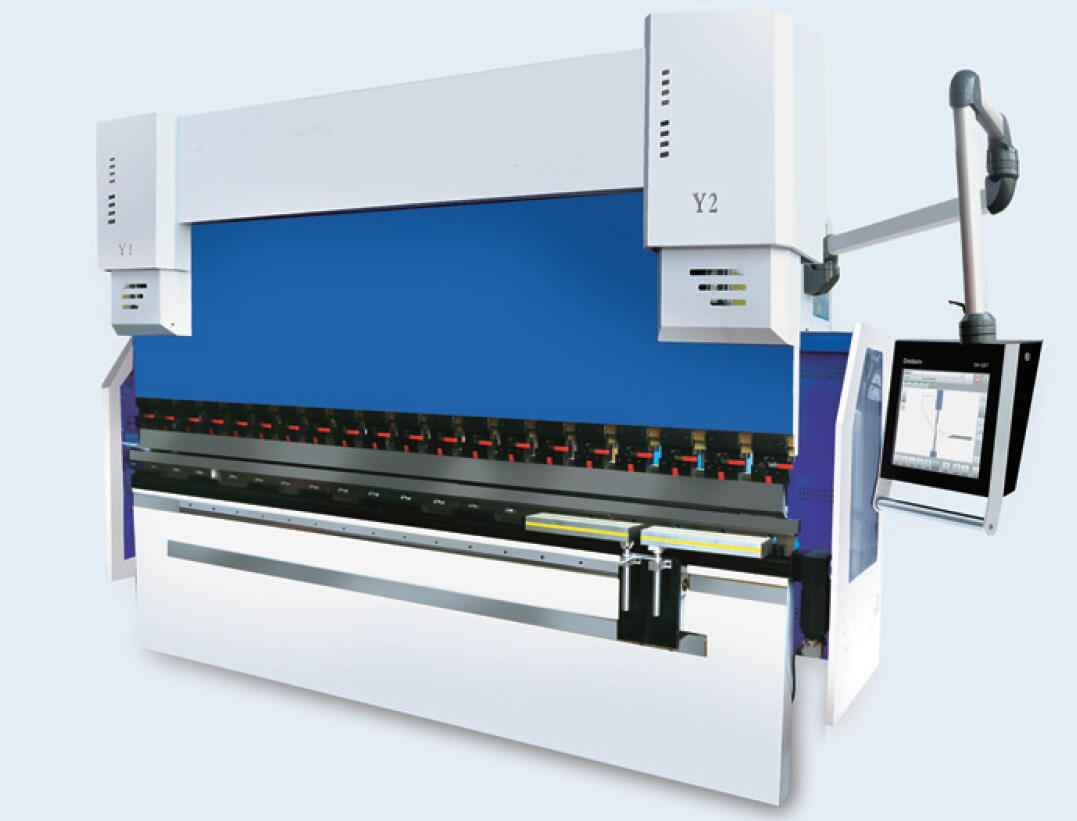

These tools fall under the most broad category of machines which involve bending flat sheet metals to different angles. They are as simple as manual bench-top models and as complex as industrial CNC systems. Some of the criteria for these machines includes die opening (10-200mm), bending length (0.5-12m), and thickness capacity (0.3-50mm). For metal furniture production, the machines allow precise edge banding and flange formation with a height tolerance of ±1mm and production rate of 500 parts/hour for simple L brackets.