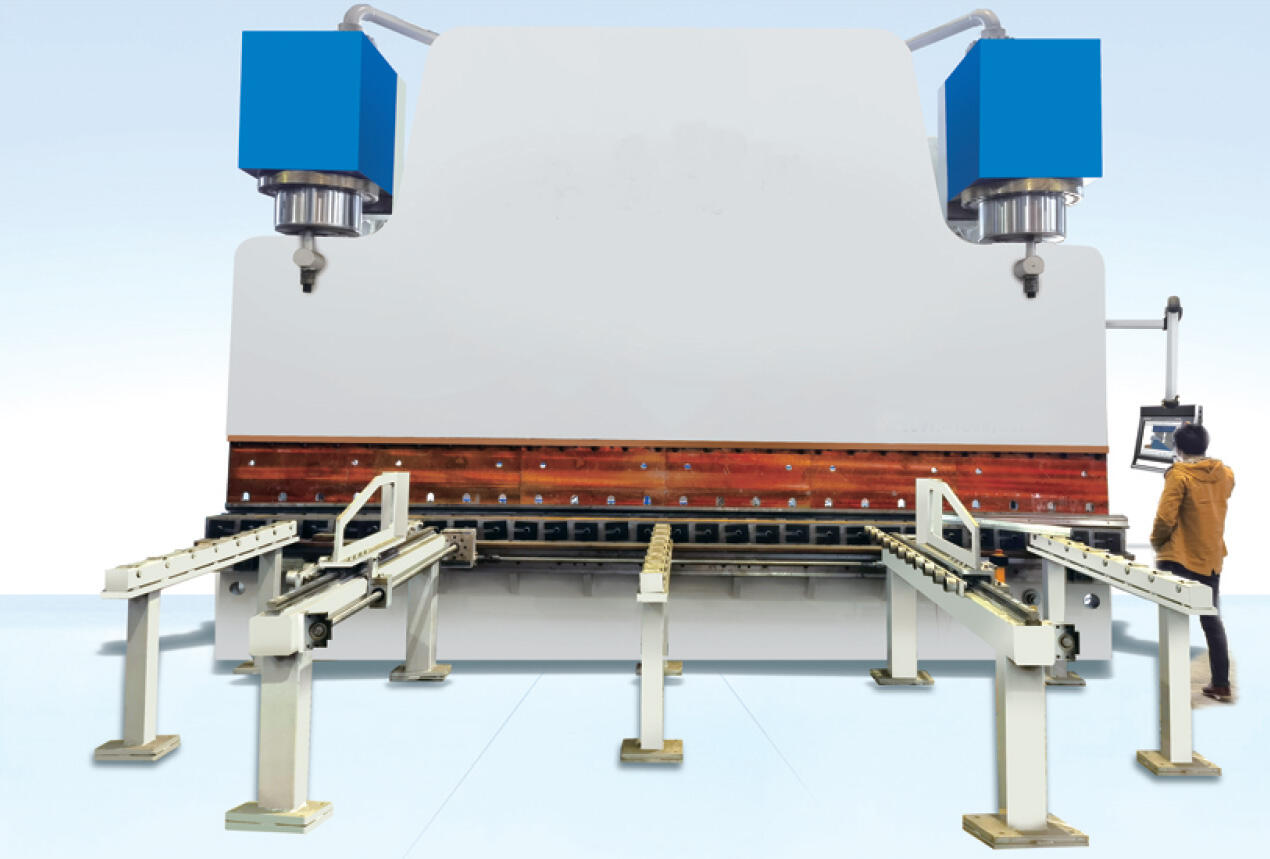

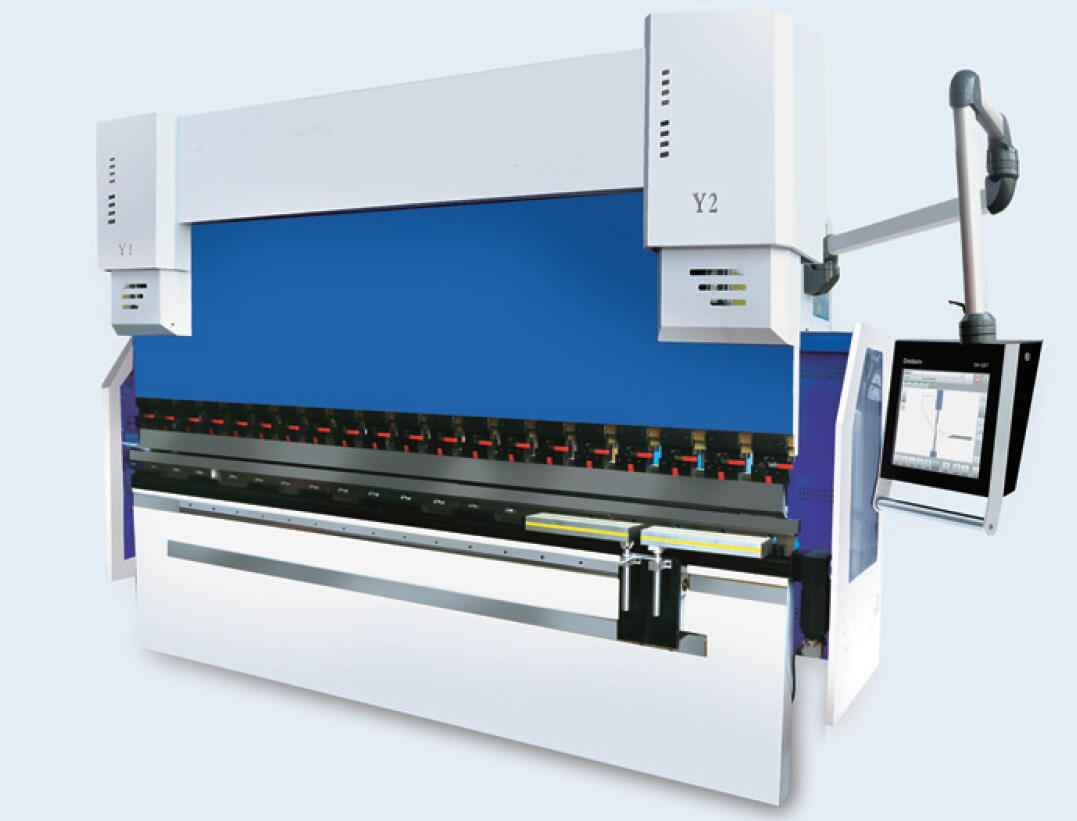

An automatic shearing machine is a high efficiency industrial device designed to cut metal sheets, plates, or profiles into precise lengths or shapes with minimal manual intervention, widely used in industries such as steel processing, automotive manufacturing, and construction. Equipped with advanced control systems—typically PLC (Programmable Logic Controller) or CNC—these machines automate key processes including material feeding, positioning, cutting, and waste ejection, significantly boosting production rates compared to manual or semi automatic alternatives. Common types include guillotine shears (with a straight blade for straight cuts) and swing beam shears (with a pivoting blade for reduced distortion in thick materials), each tailored to specific material thicknesses (from 0.1mm thin sheets to 50mm thick plates) and types (mild steel, stainless steel, aluminum). The core advantage of automatic shearing machines lies in their precision: modern models achieve cutting tolerances of ±0.1mm, ensuring uniformity in batch production, which is critical for downstream processes like welding or assembly. Safety features such as light curtains, emergency stops, and blade guards comply with global standards (OSHA, CE), protecting operators while maintaining productivity. Many machines also integrate with material handling systems—conveyors, stackers, or robotic arms—creating fully automated production lines that operate 24/7 with minimal supervision. WondersunM’s automatic shearing machines embody robust engineering and user centric design, built with high strength steel frames to withstand the forces of heavy duty cutting, minimizing deflection and ensuring consistent results. Their CNC controlled models feature intuitive HMI (Human Machine Interface) panels, allowing operators to program cutting lengths, quantities, and sequences with ease, while memory functions store frequently used recipes for quick recall. Customization options include adjustable blade gaps (to match material thickness), variable cutting speeds (for different metals), and integrated sensors for automatic thickness detection, optimizing cut quality across diverse materials. As part of WondersunM’s one stop industrial solutions, these machines integrate with their material handling equipment and quality inspection tools, streamlining workflows. Technical support includes on site installation, operator training, and remote diagnostics, ensuring minimal downtime. Exported globally, they meet international safety and performance standards, making them a reliable choice for manufacturers in Europe, Asia, and the Americas seeking to enhance efficiency in metal processing operations.