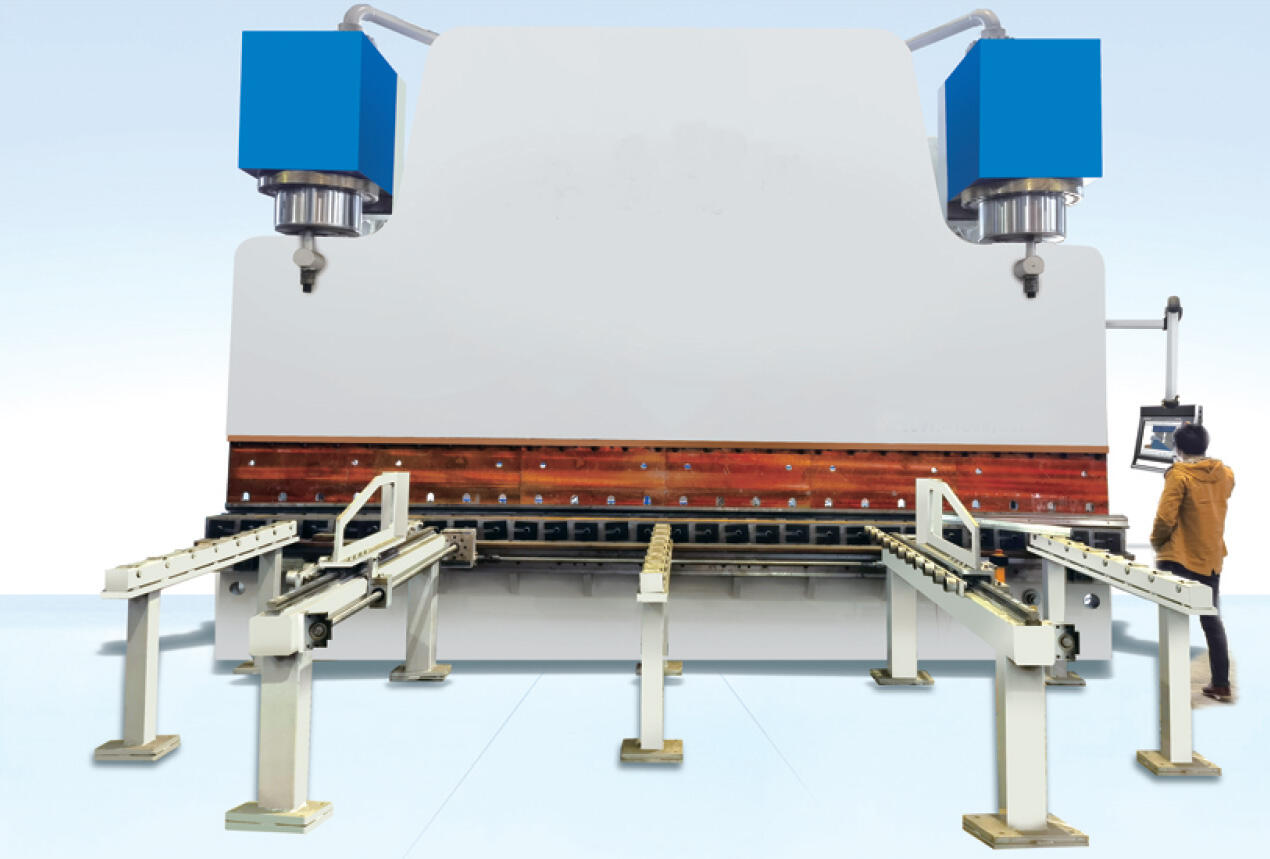

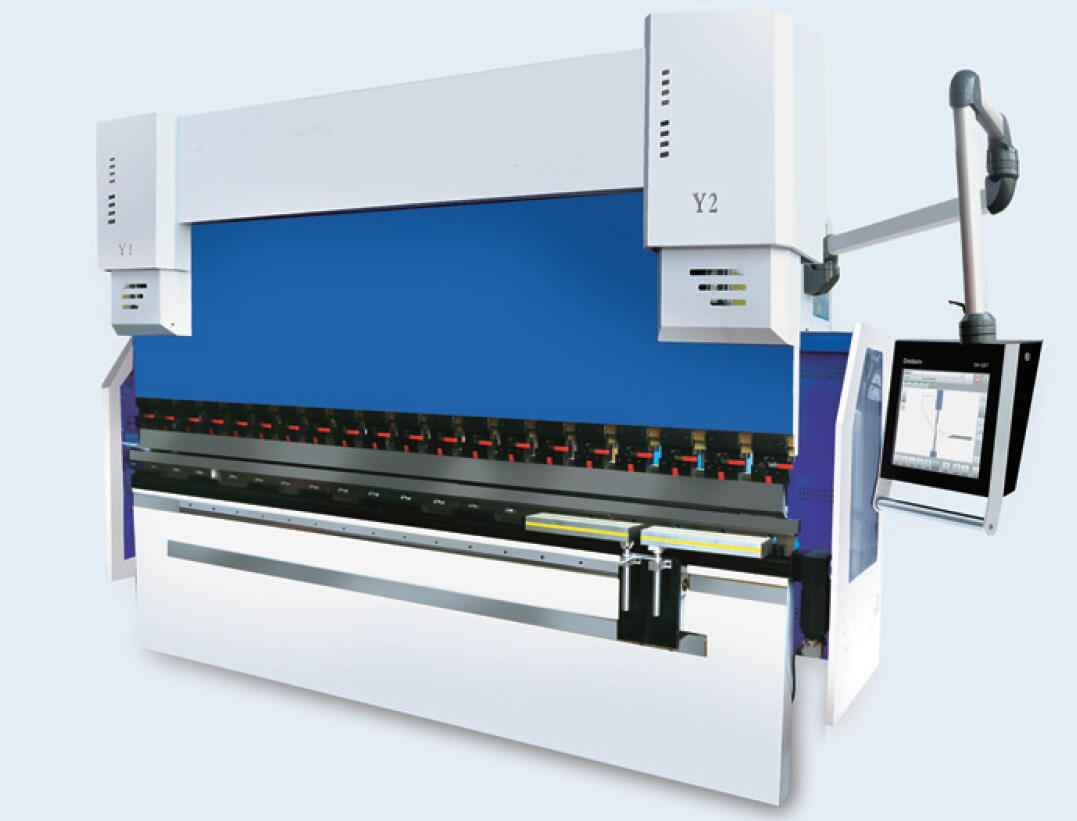

These servo-controlled motorized machines are quieter (noise ≤75dB) and more energy-efficient (power consumption is 30% lower than hydraulic system) than their predecessors. They can bend sheets of 0.5-6mm thickness at speeds of 20m/min. Touchscreen interfaces enable the storage of over 1000 bend sequences, allowing for easy retrieval and quick access. These machines are appropriate for mass production of automotive body panels and appliances since they provide uniformity in repetitive bends (angle deviation ≤±0.3°).