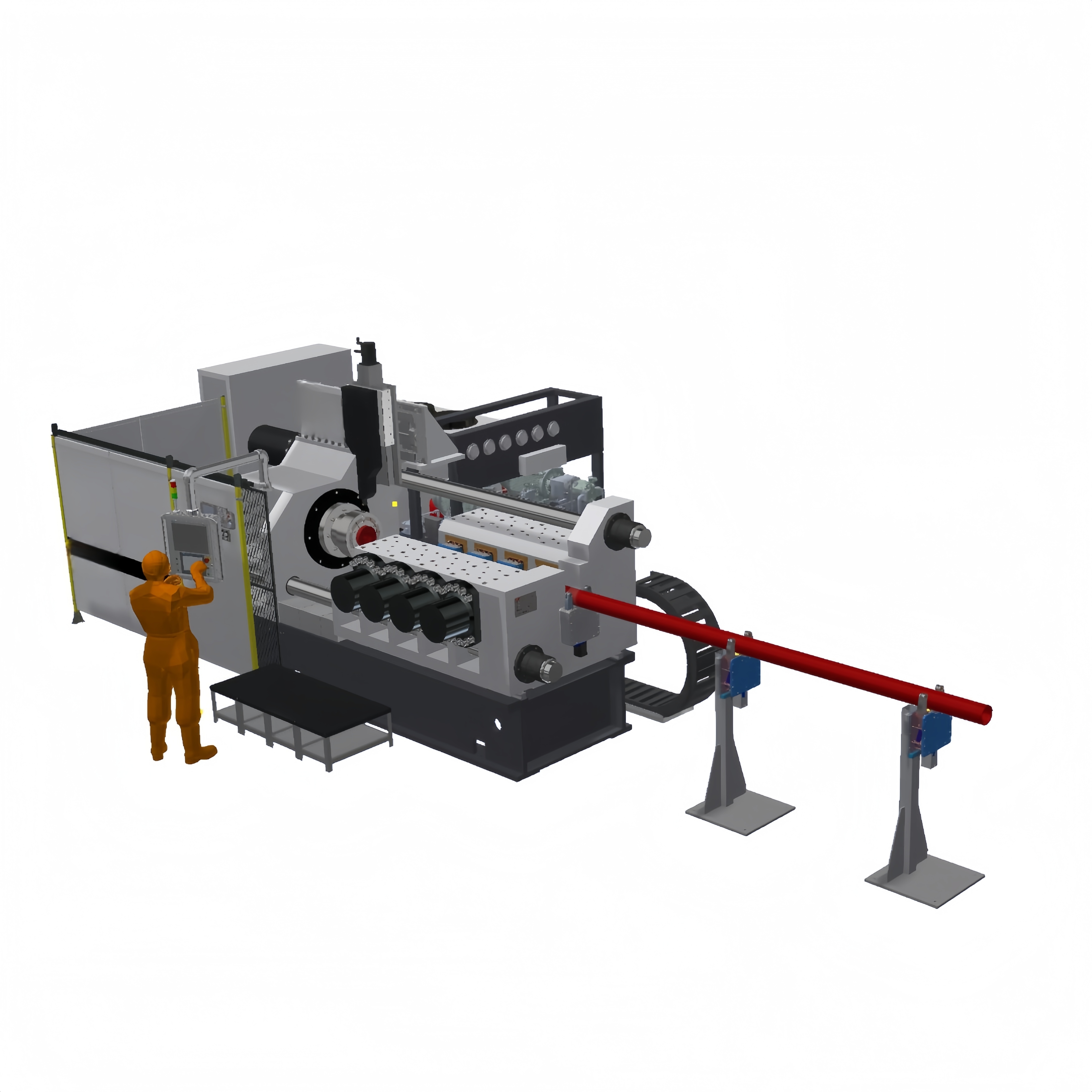

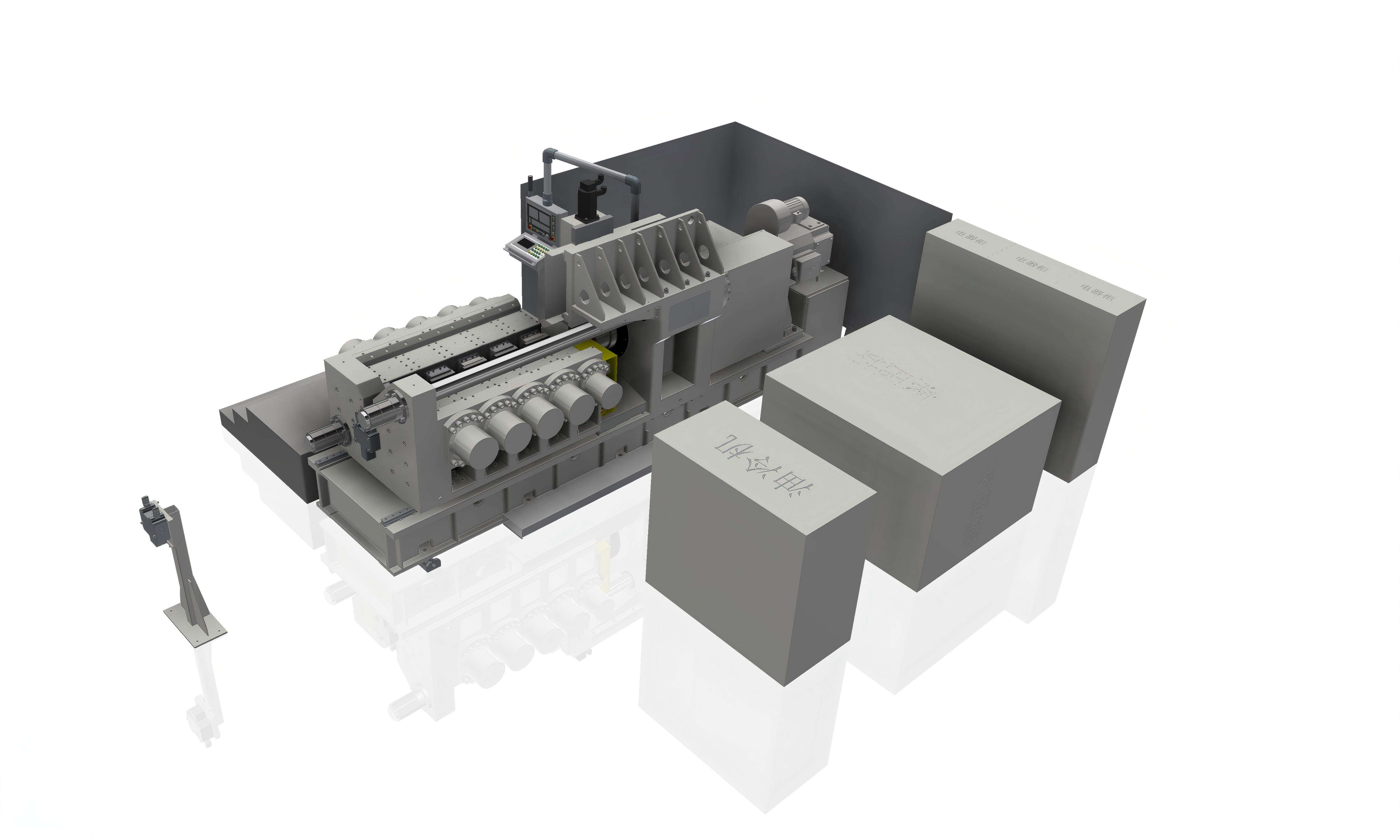

A friction welder is a versatile industrial machine that creates metallurgical bonds between materials through solid state welding, utilizing frictional heat generated by controlled relative motion between workpieces. Unlike fusion welding, this process avoids melting, eliminating defects such as porosity, segregation, and thermal cracking, resulting in joints with tensile strength often exceeding the parent material. Friction welders operate in two primary modes: rotational (one workpiece rotates against a stationary counterpart) and linear (reciprocating motion), with inertia and direct drive systems catering to different applications. The welding cycle involves three phases: friction (generating heat to plasticize the interface), burn off (expelling oxides and contaminants), and upset (applying axial pressure to forge the bond). This makes them ideal for joining dissimilar metals—e.g., steel to copper (electrical connectors), aluminum to magnesium (automotive parts), and titanium to stainless steel (aerospace components). WondersunM’s friction welders feature PLC based control systems with touchscreen interfaces, enabling precise adjustment of rotational speed (500 10,000 RPM), friction pressure (10 500 kN), and upset distance (0.1 20mm). Their portfolio includes bench top models for small components (e.g., 5mm diameter fasteners) and large scale systems for heavy industries (e.g., 500mm diameter drill pipes). Equipped with load cells and infrared temperature sensors, these machines provide real time process monitoring, ensuring compliance with standards like ISO 15620 and AWS D10.10. The company’s 25+ years of expertise in friction welding technology enables customization for specialized applications, such as orbital friction welding for non circular parts. Exported to 100+ countries, WondersunM’s friction welders are supported by on site commissioning, operator certification, and spare parts logistics, making them a trusted solution for industries requiring reliable, high strength joints.