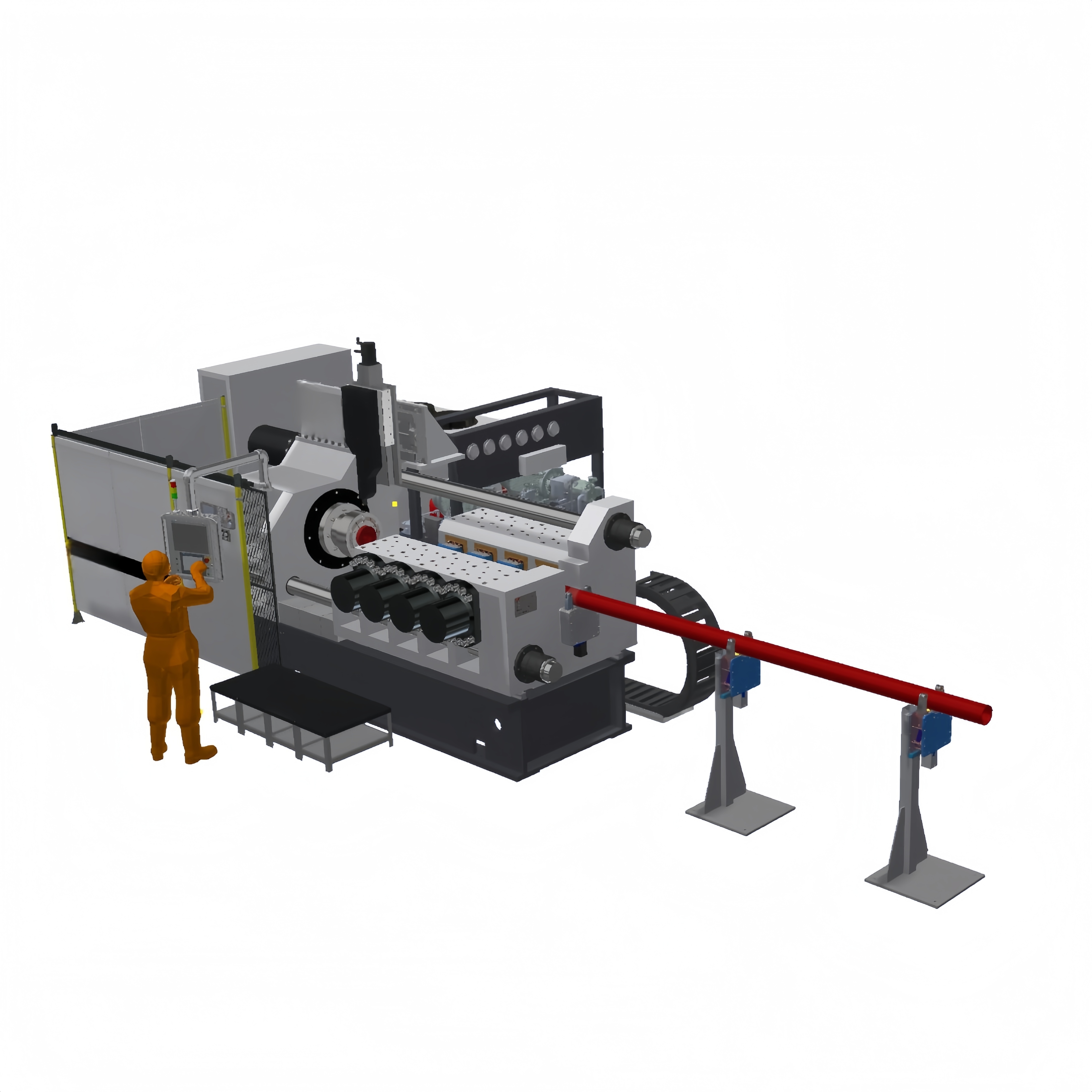

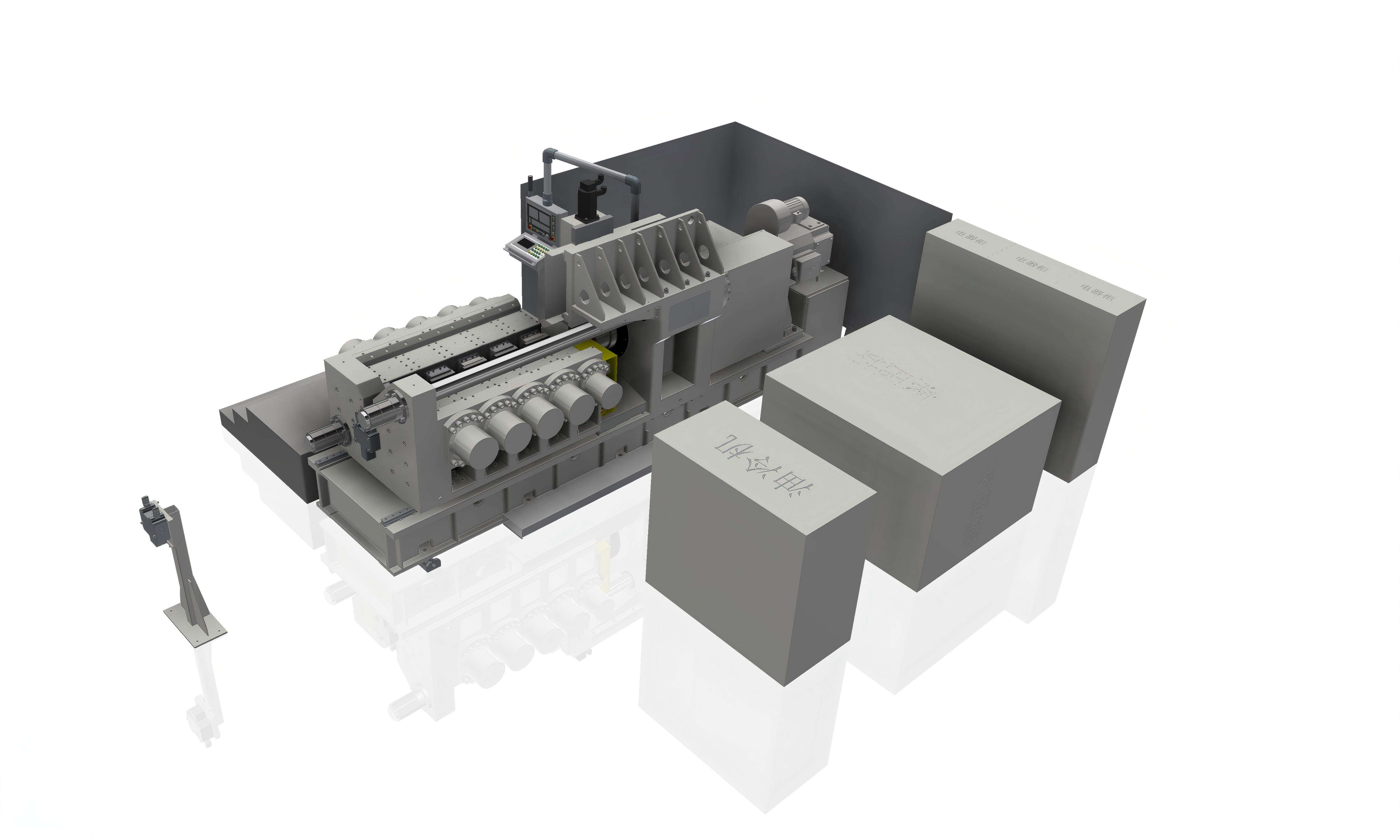

Aluminum alloy friction welding machines are specialized systems engineered to address the unique metallurgical challenges of joining aluminum alloys, which are integral to lightweight engineering in aerospace, automotive, and marine industries. Aluminum’s high thermal conductivity (approximately 205 W/m·K for 6061 alloy) and the rapid formation of a dense oxide layer (Al₂O₃) make traditional fusion welding prone to defects like porosity, hot cracking, and weakened joints. Friction welding overcomes these issues through a solid state process: rotational or linear friction between workpieces generates localized heat (typically 350 550°C for aluminum), softening the material at the interface while mechanical pressure disrupts the oxide layer, ensuring a metallurgically bonded joint without melting. This results in a heat affected zone (HAZ) less than 1mm thick, preserving the alloy’s fatigue resistance critical for aircraft fuselages and automotive chassis components. These machines excel at joining dissimilar aluminum alloys (e.g., 6061 T6 to 7075 T73) and aluminum to other metals such as copper (for heat exchangers) or titanium (for aerospace structures), leveraging precise control over rotational speed (500 3000 RPM) and axial pressure (10 50 kN) to accommodate varying alloy tempers. WondersunM’s aluminum alloy friction welding machines integrate servo hydraulic systems for pressure regulation and optical sensors to monitor interface temperature, ensuring repeatable weld quality. Their designs include quick change clamping fixtures to handle diverse geometries, from thin walled tubes (5mm diameter) to thick plates (50mm thickness). Compliance with standards like AWS C3.6M and ISO 17635 ensures compatibility with global manufacturing requirements. Backed by a technical team with expertise in aluminum metallurgy, the company offers on site parameter optimization for specific alloys, reducing setup time for clients in 100+ countries. These machines deliver cost savings by eliminating filler metals and reducing post weld machining, making them a cornerstone of modern lightweight manufacturing.