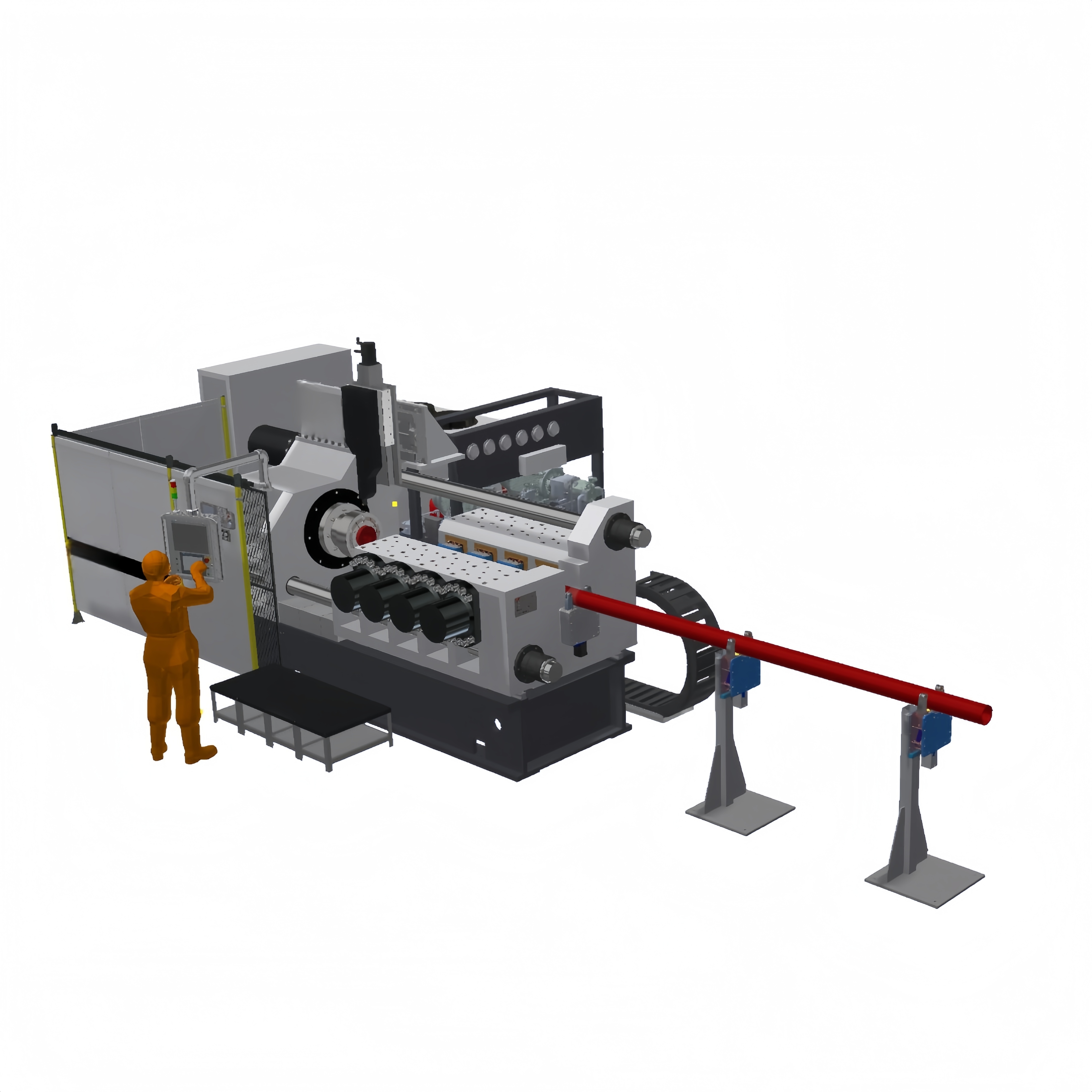

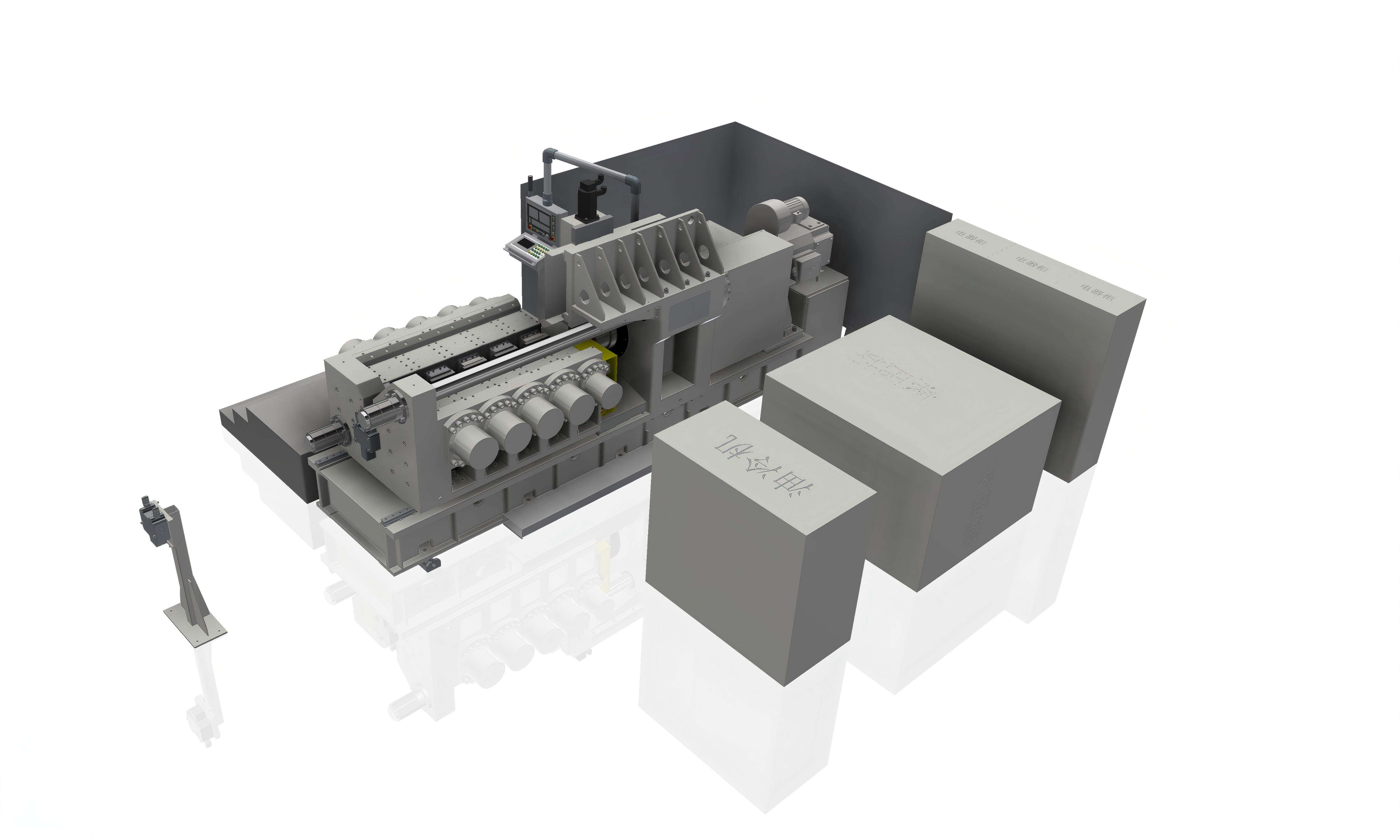

Bimetal cable lugs friction welding machines specialize in joining dissimilar metals—typically copper and aluminum in cable lugs, critical components for electrical connections in power distribution, renewable energy, and industrial wiring. Copper offers excellent conductivity, while aluminum is lightweight and cost effective, but joining them via traditional methods often leads to galvanic corrosion or weak bonds. Friction welding resolves this by creating a metallurgical bond without melting, ensuring long term conductivity and mechanical stability. The process involves rotating one metal (e.g., copper) against the other (e.g., aluminum) to generate frictional heat, followed by axial pressure to forge a seamless joint. This eliminates the need for plating or intermediary materials, reducing resistance and improving current flow. The resulting bimetal lugs resist vibration and temperature fluctuations, essential for reliable performance in harsh environments. WondersunM’s machines feature precise control over rotational speed, pressure, and duration to accommodate the differing melting points and thermal conductivities of copper and aluminum. Their R&D team offers customization for lug sizes (e.g., 10mm² to 630mm²) and shapes, ensuring compatibility with global cable standards. Backed by 25+ years of experience, the company provides technical support to optimize weld parameters, with after sales services including installation and training, catering to clients in over 100 countries. These machines are integral to producing safe, efficient electrical connections.