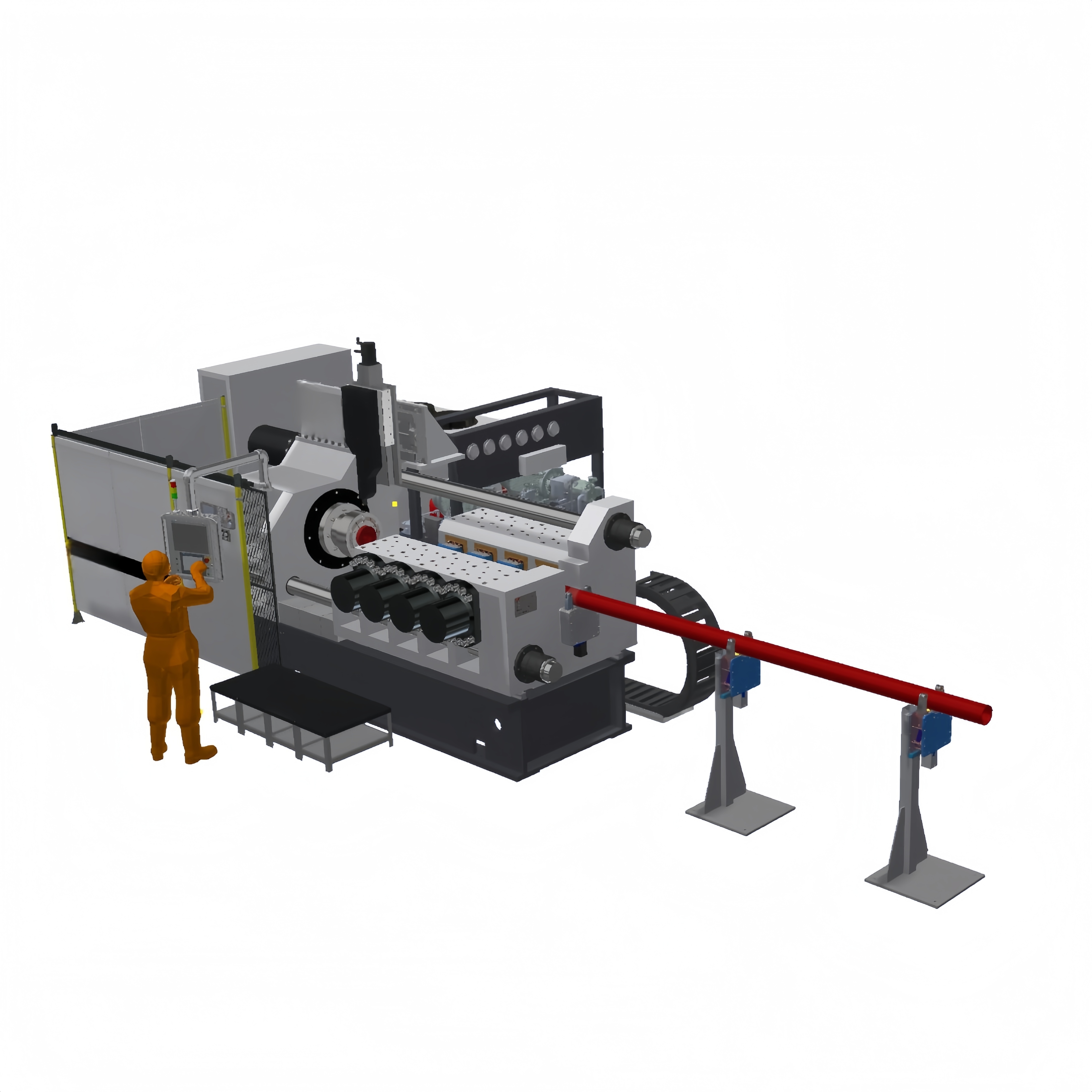

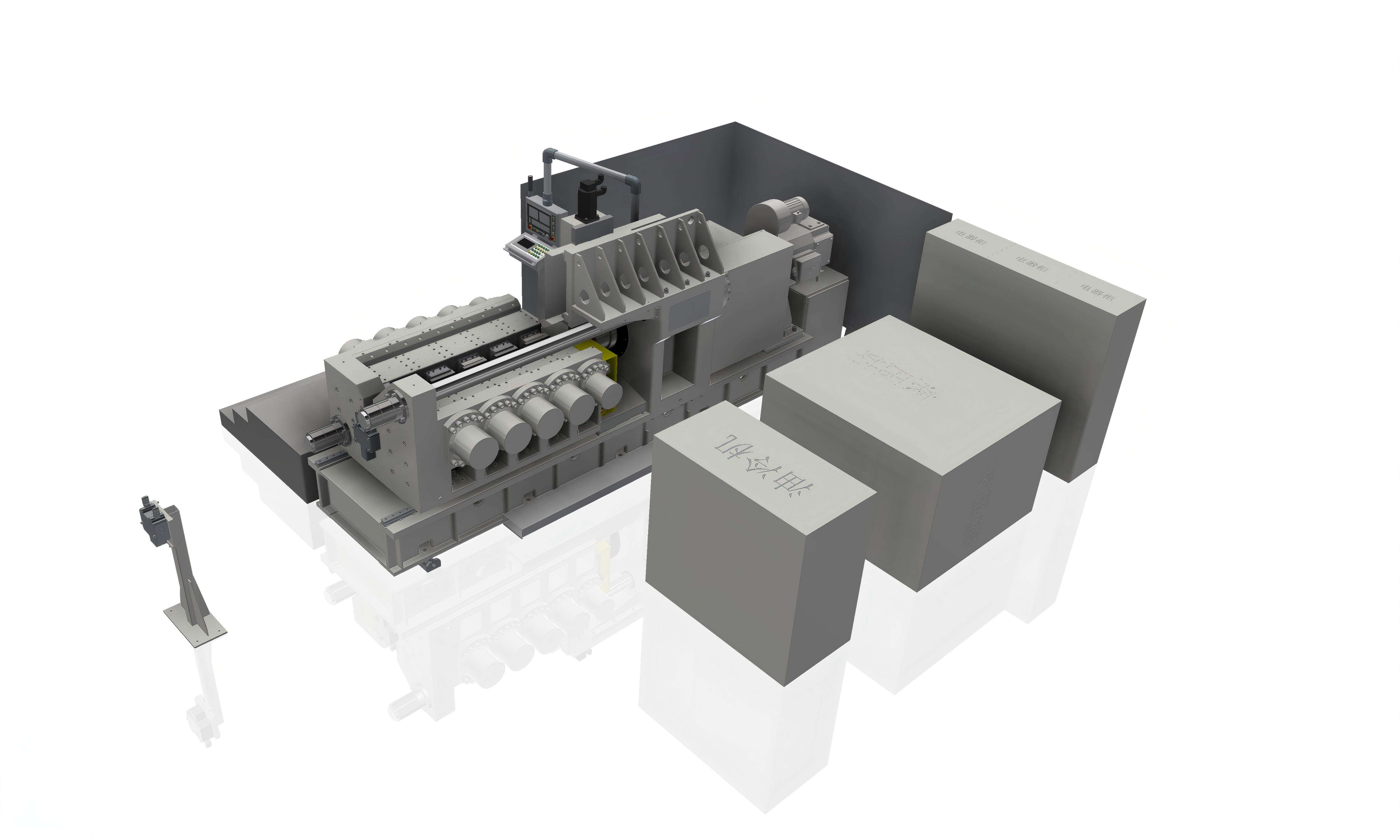

Машины для фрикционной сварки биметаллических кабельных наконечников специализируются на соединении разнородных металлов, как правило, меди и алюминия в кабельных наконечниках — критически важных компонентах электрических соединений в системах распределения электроэнергии, возобновляемых источниках энергии и промышленной электропроводке. Медь обладает отличной электропроводностью, алюминий же легкий и экономически эффективный, однако соединение этих металлов традиционными методами часто приводит к гальванической коррозии или слабым соединениям. Фрикционная сварка решает эту проблему, создавая металлическую связь без расплавления, что обеспечивает долгосрочную проводимость и механическую стабильность. Процесс включает вращение одного металла (например, меди) относительно другого (например, алюминия) для генерации тепла трения, после чего прикладывается осевое давление для формирования бесшовного соединения. Это исключает необходимость покрытий или промежуточных материалов, снижая сопротивление и улучшая токопроводимость. Полученные биметаллические наконечники устойчивы к вибрациям и перепадам температур, что имеет ключевое значение для надежной работы в тяжелых условиях. Машины WondersunM оснащены точным контролем скорости вращения, давления и времени сварки, чтобы учитывать различные температуры плавления и теплопроводность меди и алюминия. Их исследовательская команда предлагает индивидуальные решения для размеров (например, от 10 мм² до 630 мм²) и форм наконечников, обеспечивая совместимость с международными стандартами кабельной продукции. Опыт компании, насчитывающий более 25 лет, позволяет предоставлять техническую поддержку для оптимизации параметров сварки, а также послепродажное обслуживание, включающее установку и обучение, обслуживая клиентов из более чем 100 стран. Эти машины играют важную роль в производстве безопасных и эффективных электрических соединений.