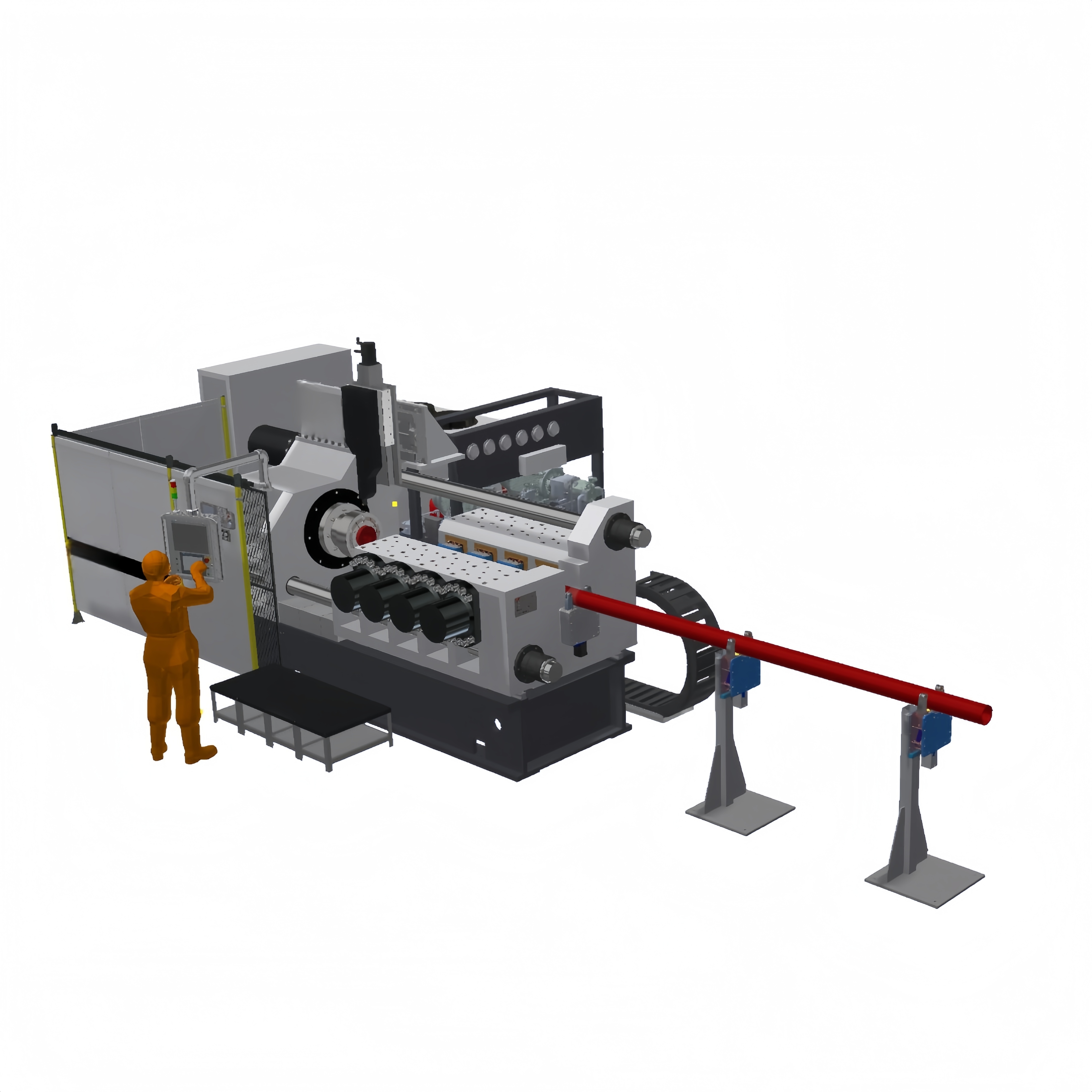

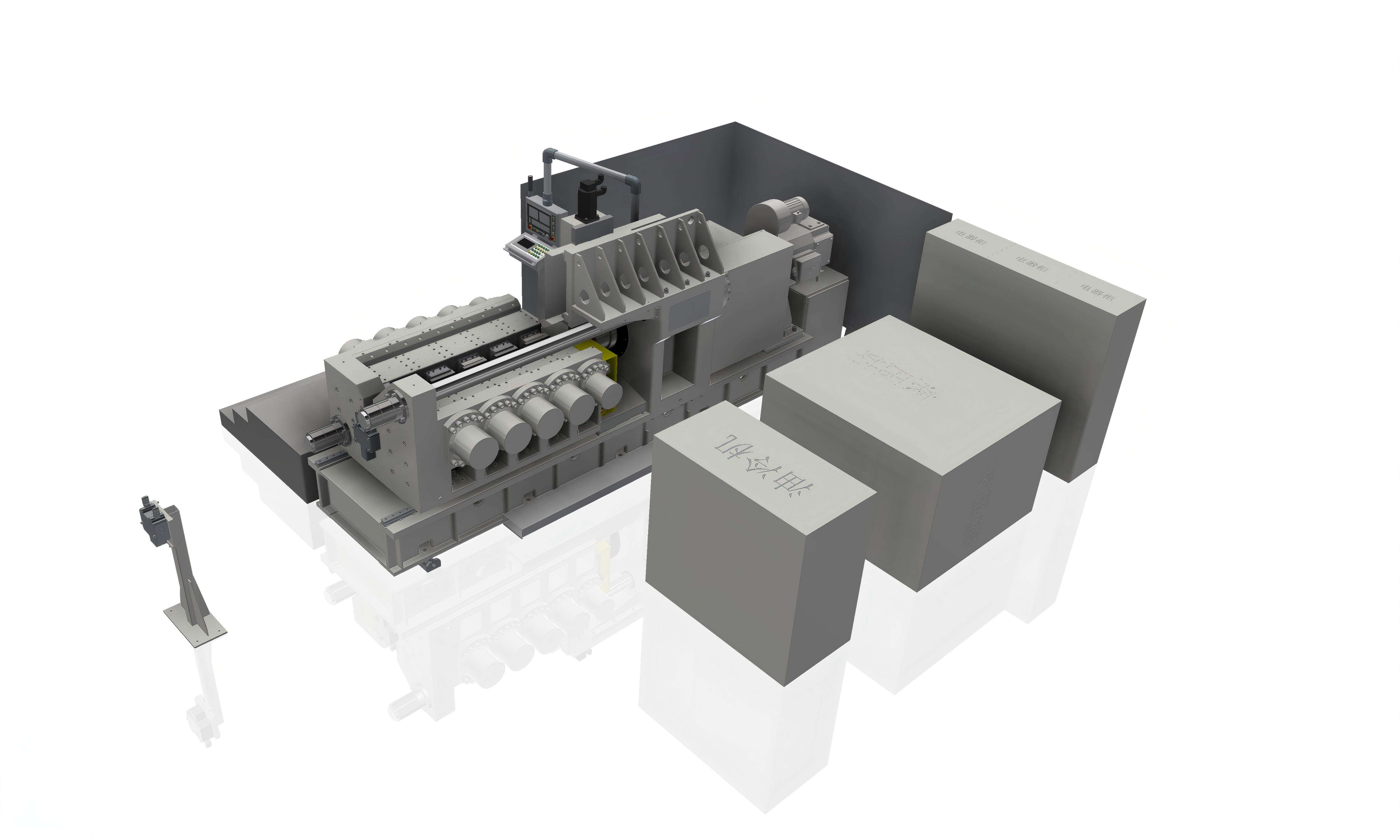

Maszyny do spawania tarcia ze stali nierdzewnej są zaprojektowane tak, aby rozwiązywać wyjątkowe wyzwania związane z łączeniem stali nierdzewnej, materiału cenionego ze względu na odporność na korozję, wytrzymałość i właściwości higieniczne, ale podatnego na takie problem Dzięki wykorzystaniu ciepła generowanego przez tarcie (zamiast otwartych płomieni lub łuków), maszyny te tworzą wiązania w stanie stałym, które minimalizują wprowadzanie ciepła, zachowując warstwę tlenku chromu, która jest kluczowa dla odporności stali nierdzew Proces ten unika stopionego metalu, zmniejsza ryzyko 晶间 korozji (korrozji międzyziarnistej) i utrzymuje mechaniczną wytrzymałość materiału, niezbędną do zastosowań w przetwórstwie żywności, sprzęcie medycznym, składowaniu chemicznym i inżynierii mor Maszyny te doskonale łączą różne klasy stali nierdzewnej (np. 304, 316) i nawet różne metale, takie jak stal nierdzewna i stal węglowa, zwiększając elastyczność projektowania. Maszyny do spawania tarcia ze stali nierdzewnej WondersunM posiadają precyzyjną kontrolę momentu obrotowego i ciśnienia, aby uwzględnić wysoką przewodność cieplną i wytrzymałość na rozciąganie materiału. Wspierane przez zespół doświadczony w handlu międzynarodowym, oferują dostosowanie wielkości części i wielkości produkcji, zapewniając zgodność ze standardami światowymi (np. ASTM, ISO). Dzięki usługom, w tym wsparciu na miejscu, maszyny te zapewniają niezawodne, wysokiej jakości złącza, co czyni je zaufanym wyborem w branżach, w których integralność materiału nie jest negocjowalna.