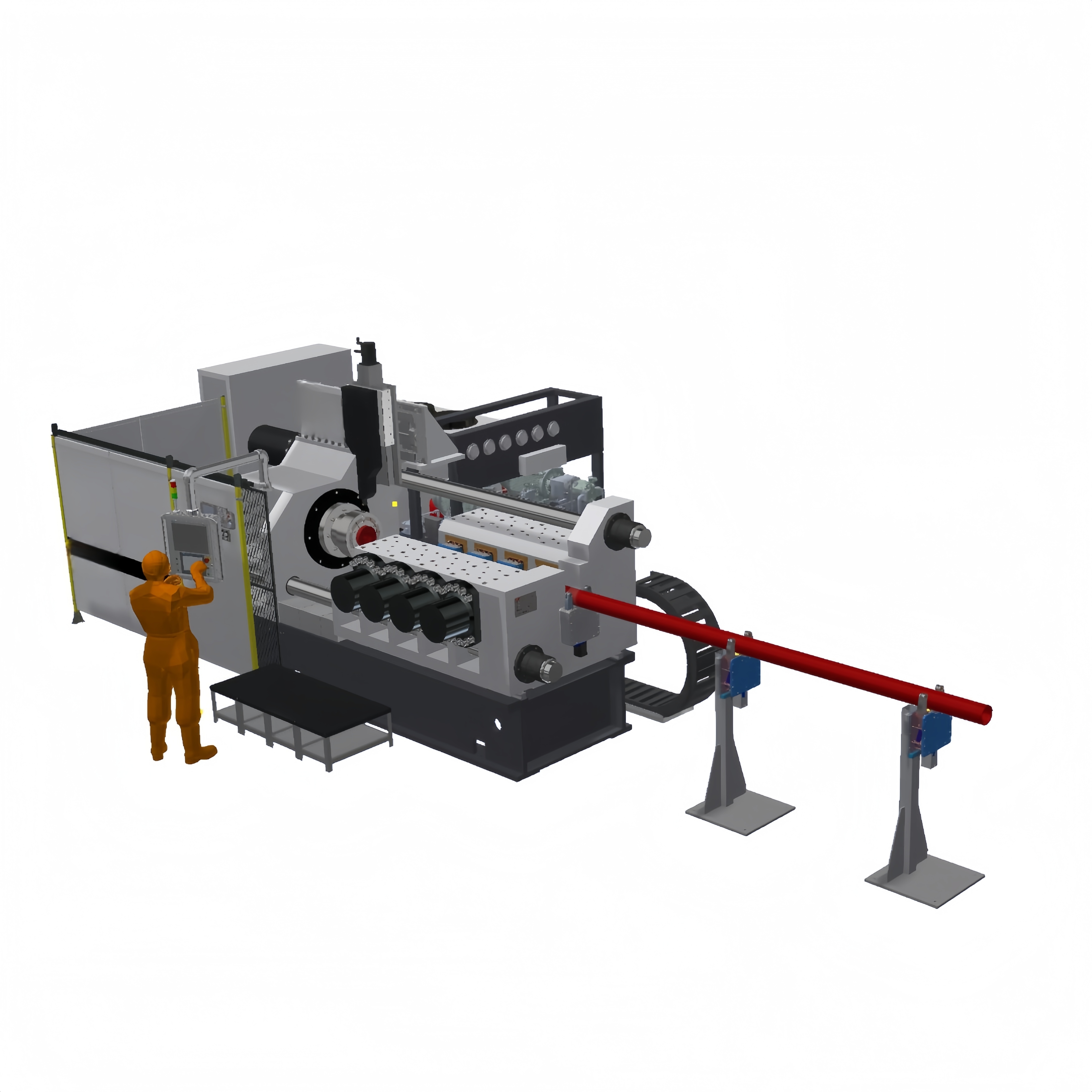

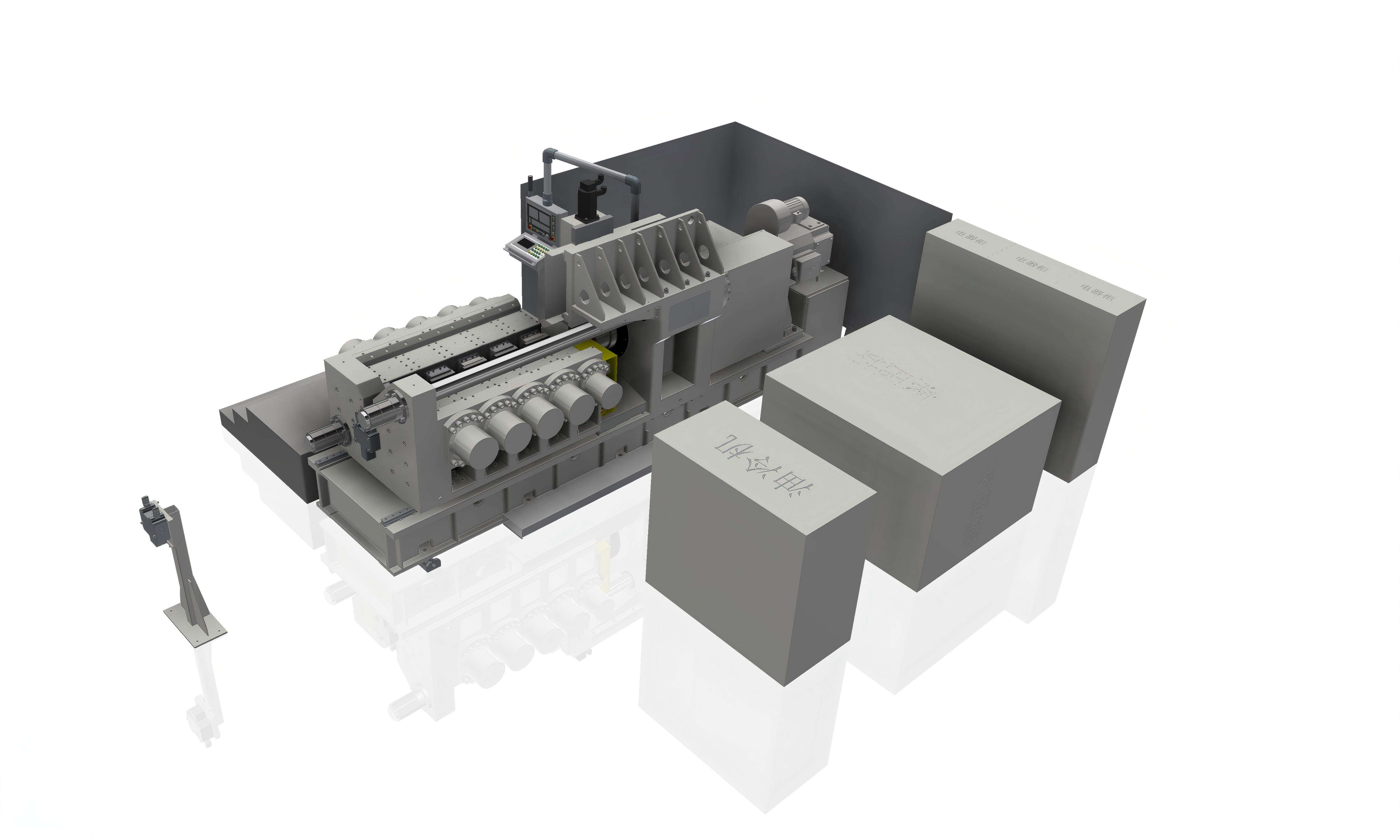

Direct drive friction welding machines are advanced systems where rotational motion is transmitted directly from the motor to the workpiece via a rigid drive mechanism, eliminating intermediate components like belts or gears. This design delivers superior torque control, precision, and responsiveness, making it ideal for applications requiring tight tolerances and consistent weld quality. The direct drive mechanism ensures immediate acceleration and deceleration, allowing for precise control over the friction time, rotational speed, and upset force—critical parameters in achieving uniform bonds. This efficiency reduces cycle times compared to indirect drive systems, boosting productivity for high volume production. These machines are particularly suited for welding small to medium sized components, such as automotive parts, aerospace fasteners, and precision mechanical parts, where even minor inconsistencies can compromise performance. WondersunM integrates advanced servo motors and digital control systems into their direct drive models, enabling real time monitoring and adjustment of welding parameters. Their 25+ years of expertise ensure robust build quality, with components designed to withstand continuous operation. Supported by a technical team familiar with global industry standards, these machines offer customization for specific materials (e.g., steel, aluminum) and part geometries, backed by comprehensive after sales service, including installation and training, to meet the needs of clients across over 100 countries.