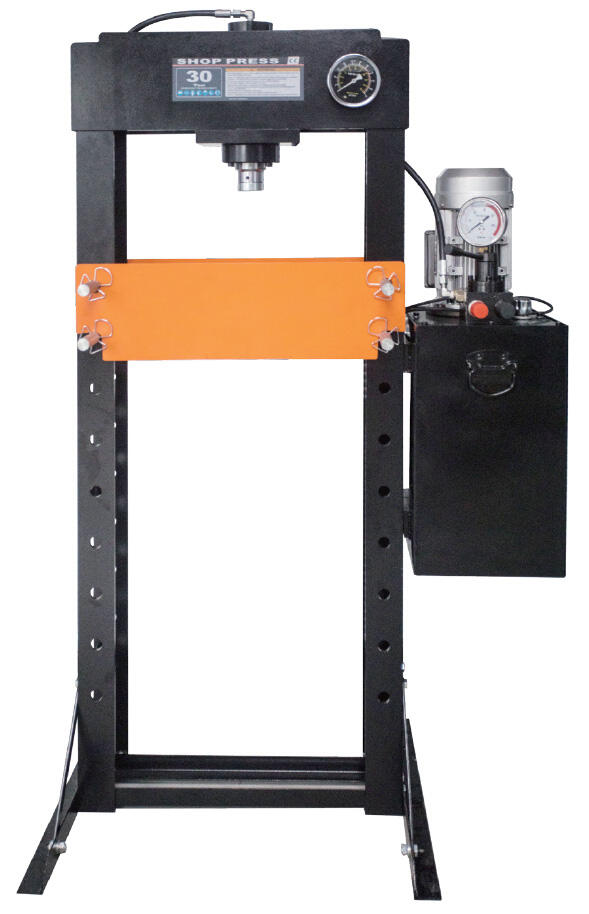

Hydraulic cylinders (100-3000 psi) output smooth continuous force with almost no vibration which permits easier rocking motions. Exact control is also possible with a precision force measurement display with ±1% accuracy. For more demanding vertical activities such as metal stamping and frame straightening, these presses are capable of greater heavy-duty applications with high force 20-500 tons. Multi-stage industrial models are popular in automotive OEM and heavy equipment manufacturing because of their de-coupled reduced cycle time.