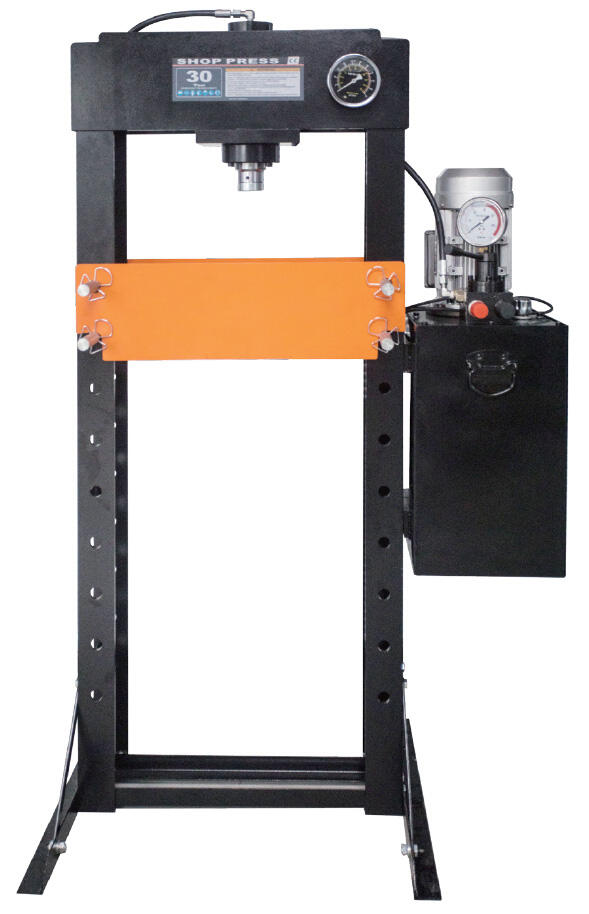

Presses with pneumatic and hydraulic controls and safety valves for damage prevention, Overforce - Prevents Damage e.g. ≥100 tons These devices have overload protection devices like shear pins and pressure relief valves are designed to break at certain levels to protect workpieces and dies. These devices have high application in metal forming and automotive assembly where precision controlled press forces (tolerance ±5%) respeted with OSHA 1910.217 standards for mechanical power presses.