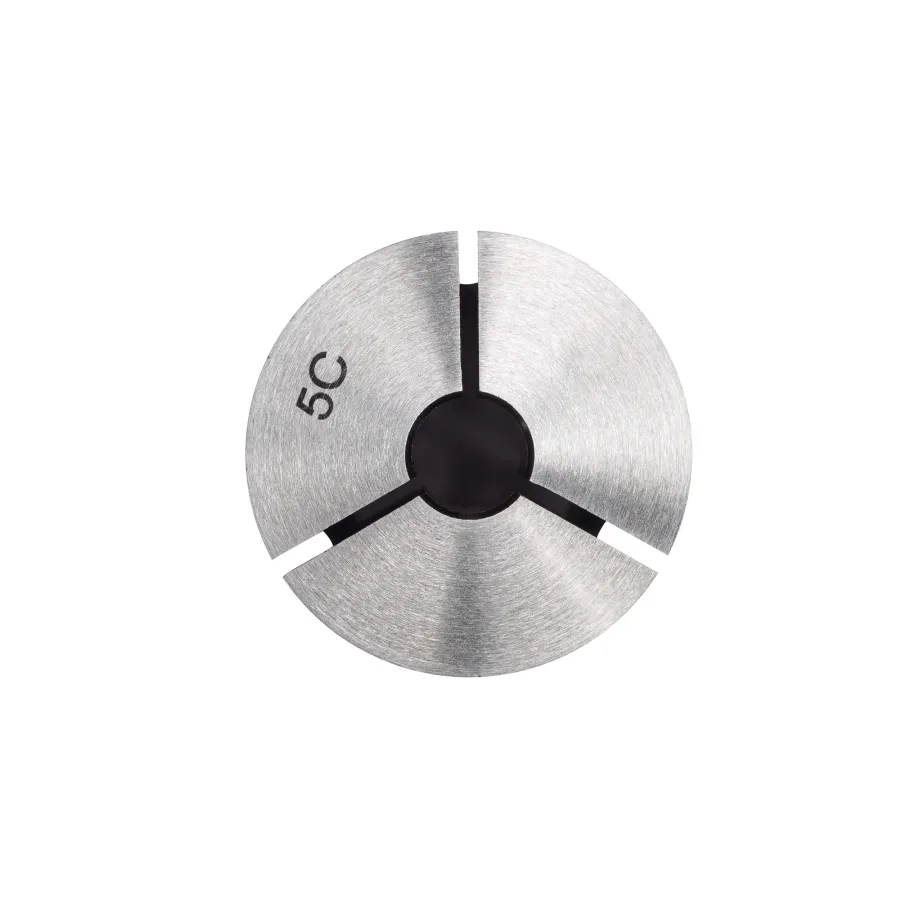

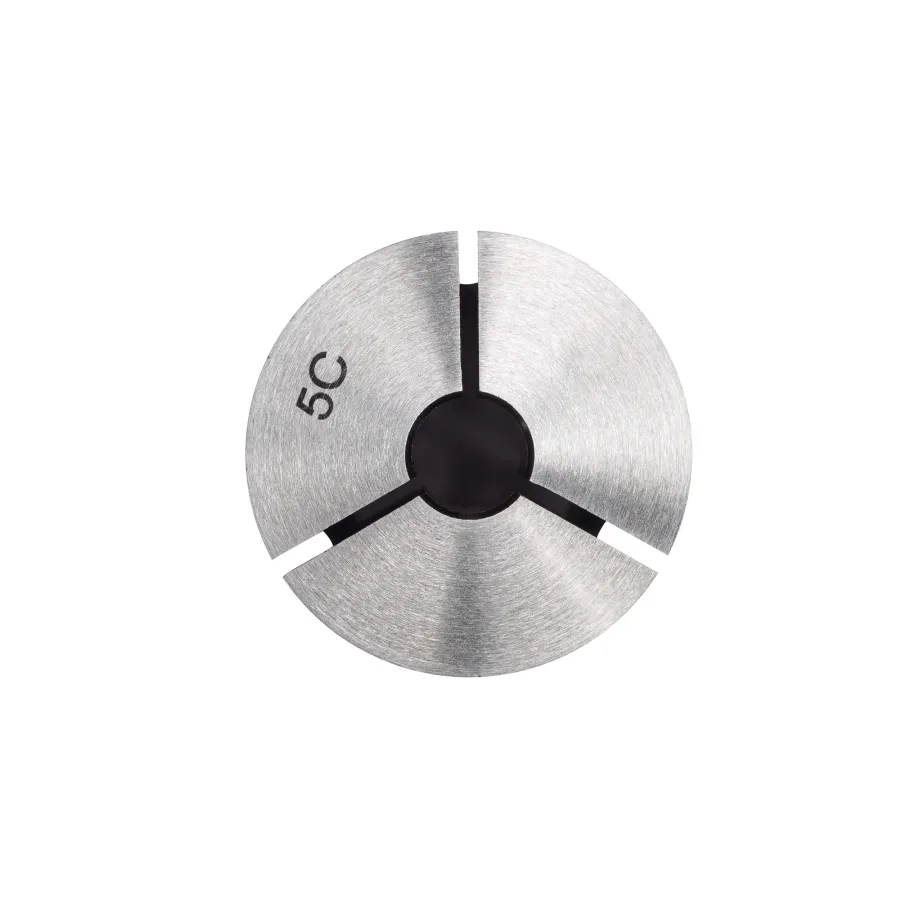

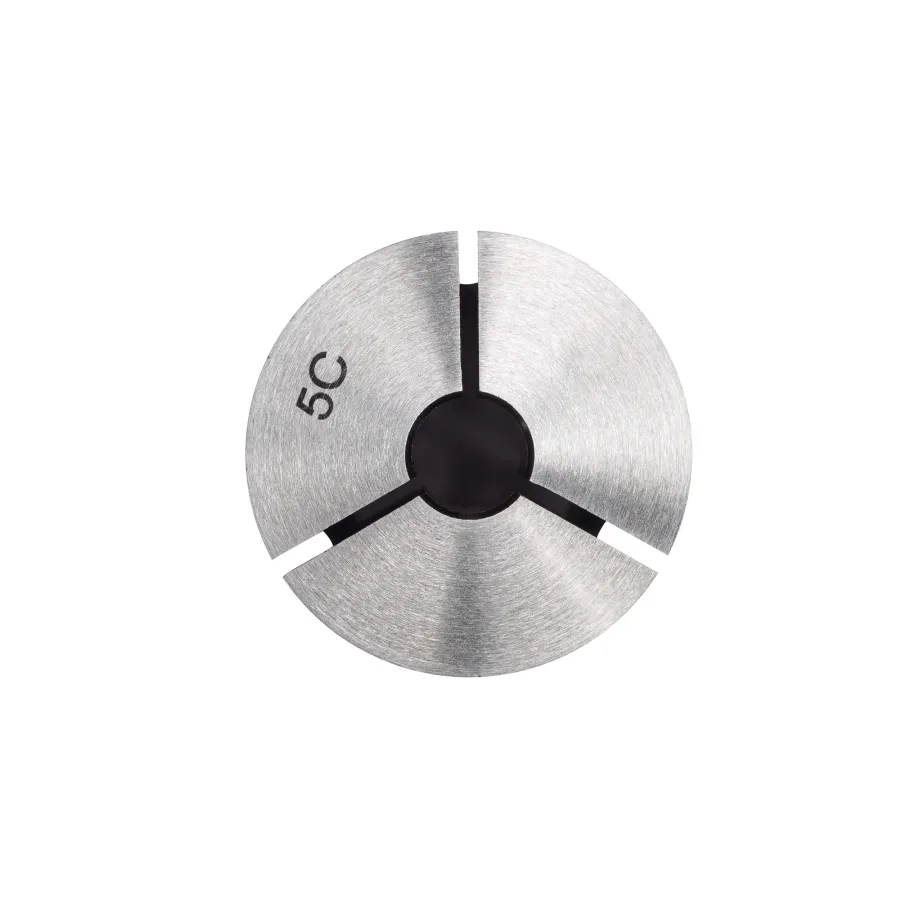

Cohronics developed coolant ER collets for guide spiral groove internal coolant delivery for better efficiency of chip evacuation. They also optimize thermal ablation: coolant is provided under high pressure at the cutting edge (20MPa) during machining which decreases tool temperature more than 30% in deep milling or drilling. Clamping within 0.01mm runout provides stability of tools at high speeds (up to 25,000rpm). Spiral grooves further enhance chip removal, increasig utility of ER collets for deep-hole machining in heat resistant alloys. These tools, compared to standard collets, decrease machining costs by 20-40% due to extended tool life.