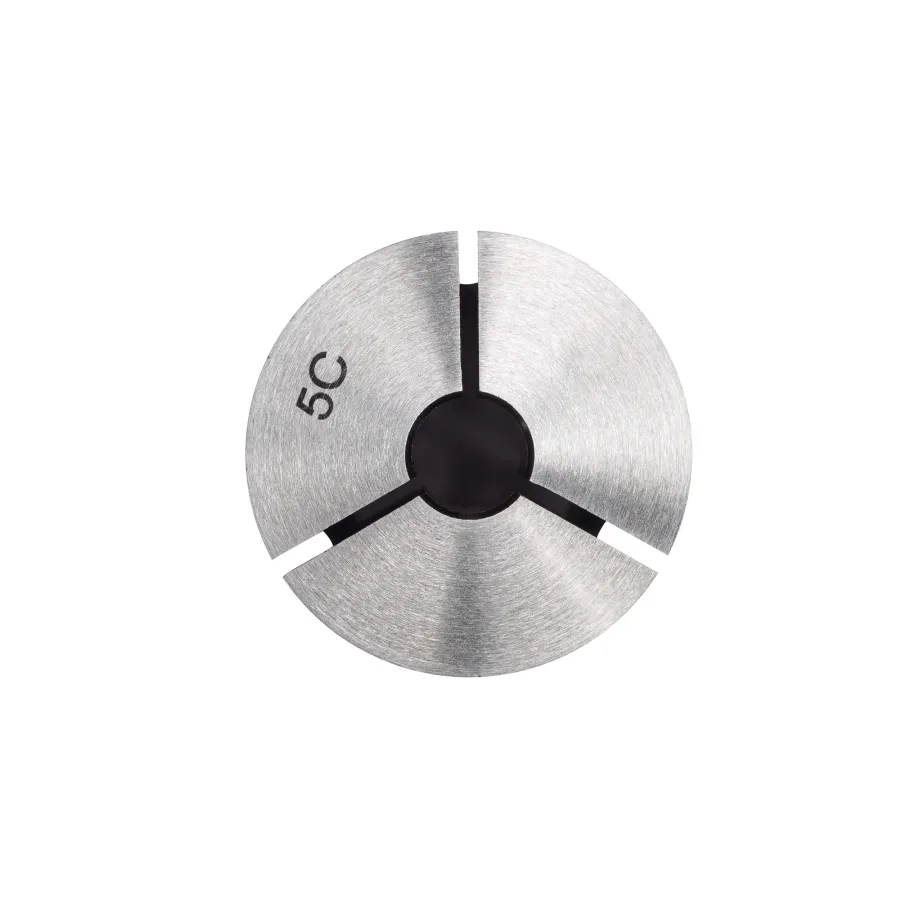

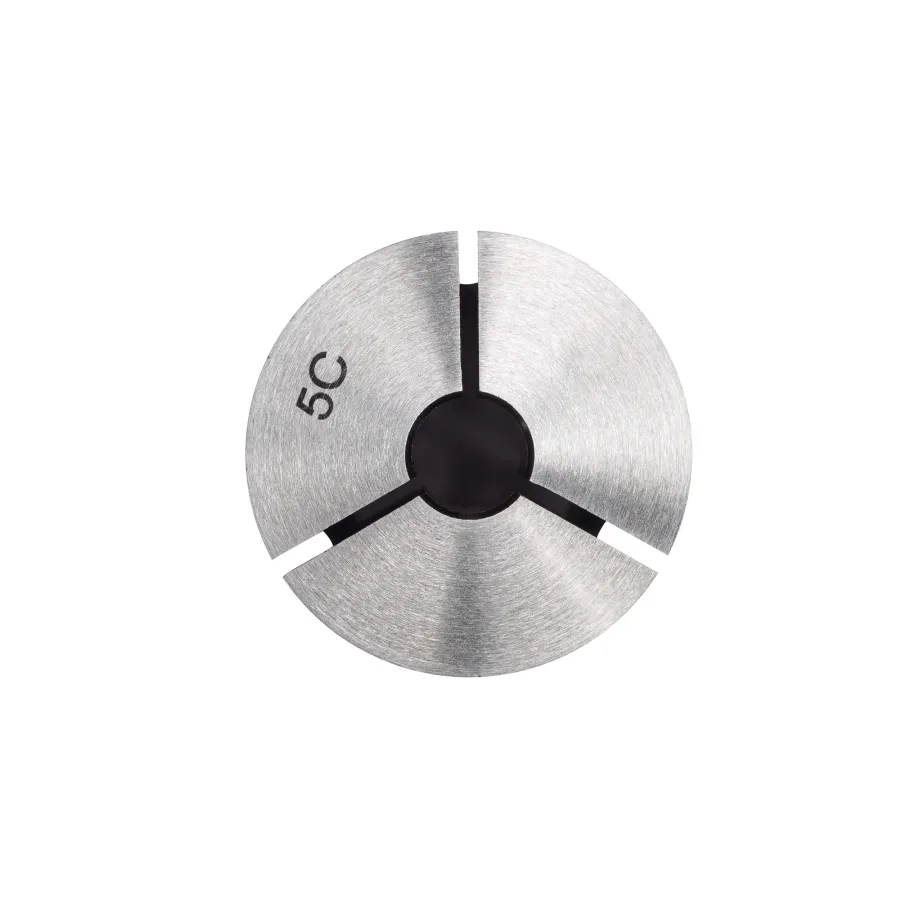

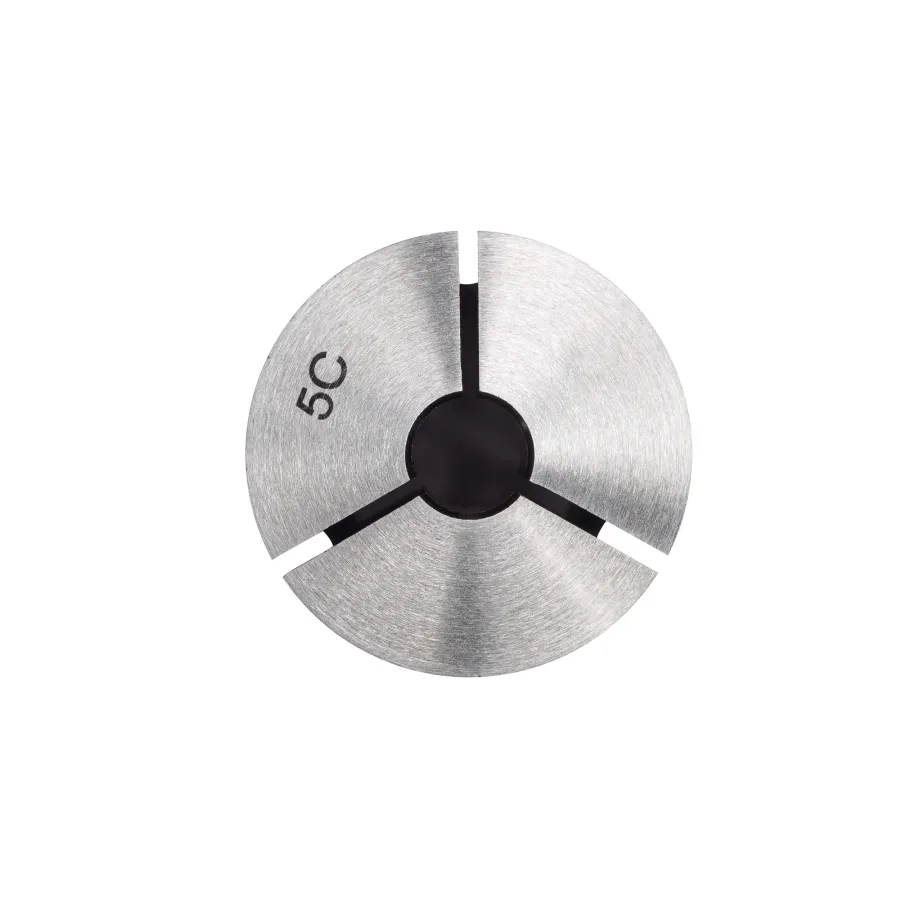

ER Collet: Elastic Tool Holder with Wide Applications

A type of tool holder with an elastic collet structure, clamping tools by tightening nuts. It has a wide clamping range, quick tool change, and common specifications like ER11/ER16/ER20, suitable for holding small-diameter milling cutters and drills with ±0.01mm precision, widely used in small-to-medium CNC machining centers.

Get A Quote