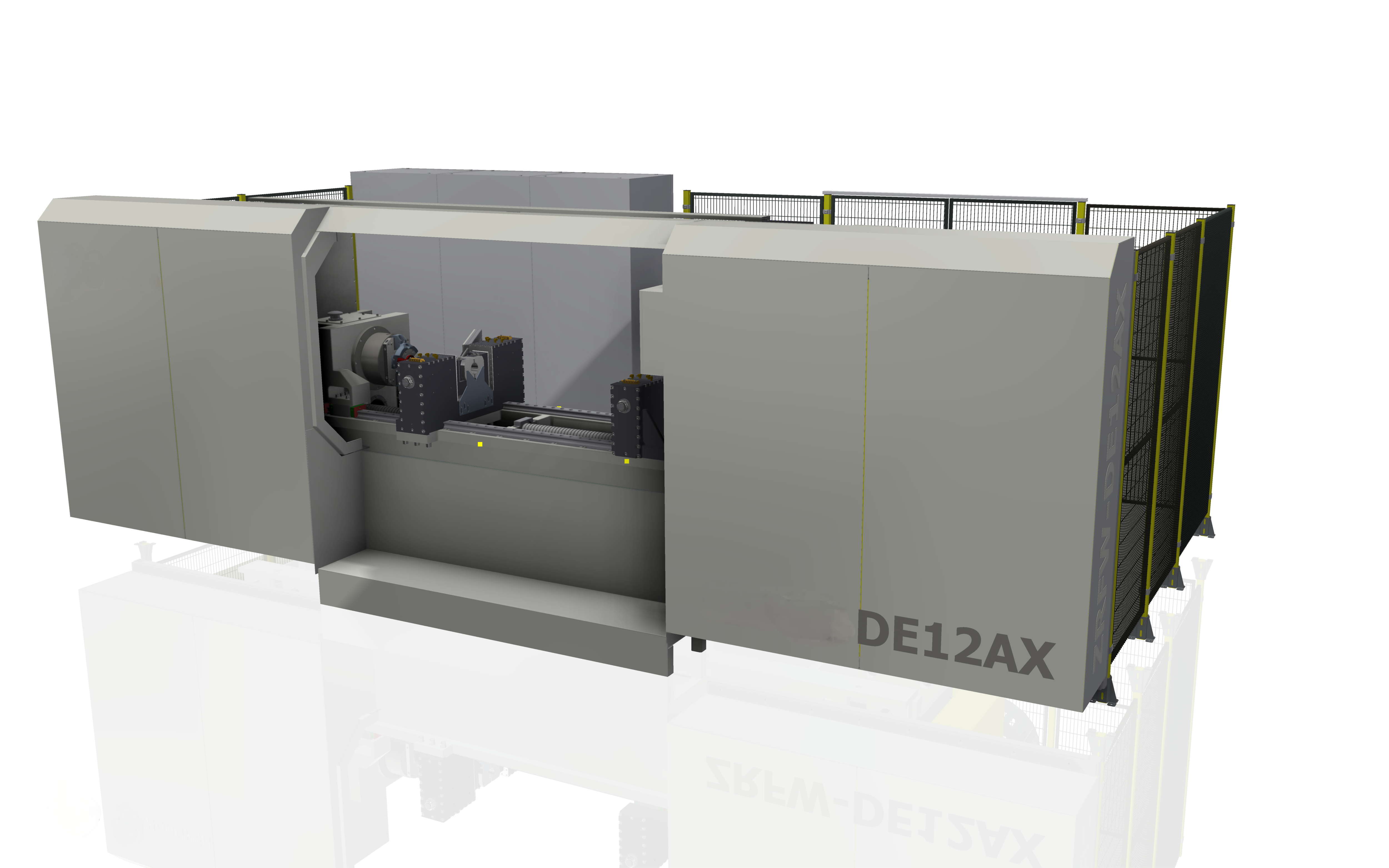

เครื่องเชื่อมด้วยแรงเสียดทานเป็นระบบที่ใช้ในอุตสาหกรรมที่มีความหลากหลาย ซึ่งใช้หลักการเชื่อมโลหะแบบบอนด์สถานะของแข็ง โดยใช้ความร้อนจากแรงเสียดทานที่เกิดจากการเคลื่อนที่สัมพัทธ์กันของชิ้นงาน กระบวนการนี้ไม่ทำให้โลหะหลอมละลาย จึงหลีกเลี่ยงปัญหา เช่น รูพรุน การแตกร้าว หรือการแยกตัวของโลหะผสม ซึ่งพบได้บ่อยในการเชื่อมแบบหลอมละลาย ส่งผลให้รอยเชื่อมมีความแข็งแรงมักสูงกว่าวัสดุเดิม เครื่องเหล่านี้สามารถทำงานในรูปแบบต่าง ๆ (เช่น การขับเคลื่อนตรง อินเนอร์เชียล) เพื่อรองรับการใช้งานในหลากหลายอุตสาหกรรม เช่น ยานยนต์ (เพลา ฟันเฟือง) อากาศยาน (ชิ้นส่วนเครื่องยนต์) พลังงาน (ท่อกลมเจาะ) และการก่อสร้าง (เหล็กเส้น) จุดเด่นหลัก ได้แก่ ความสามารถในการเชื่อมโลหะต่างชนิดกัน (เช่น ทองแดงกับอลูมิเนียม เหล็กกับทังสเตนคาร์ไบด์) ของเสียจากการผลิตน้อย และประสิทธิภาพการผลิตสูง WondersunM ผู้ผลิตชั้นนำที่มีประสบการณ์มากกว่า 25 ปี มีเครื่องเชื่อมด้วยแรงเสียดทานหลากหลายรุ่น ตั้งแต่เครื่องขนาดเล็กสำหรับชิ้นส่วนขนาดเล็กไปจนถึงระบบขนาดใหญ่สำหรับชิ้นส่วนหนัก อุปกรณ์ของบริษัทมีระบบควบคุมขั้นสูงที่ช่วยให้ปรับตั้งค่าต่าง ๆ ได้อย่างแม่นยำ (เช่น ความเร็วรอบ แรงดัน เวลา) และมีทีมงานมืออาชีพที่คอยให้บริการปรับแต่ง การติดตั้ง และการฝึกอบรม เครื่องจักรถูกส่งออกไปยังกว่า 100 ประเทศ สะท้อนถึงความมุ่งมั่นของแบรนด์ในเรื่องคุณภาพ สมรรถนะ และการเป็นผู้ให้บริการครบวงจรสำหรับอุตสาหกรรม ที่สามารถตอบสนองความต้องการที่หลากหลายของลูกค้าทั่วโลก