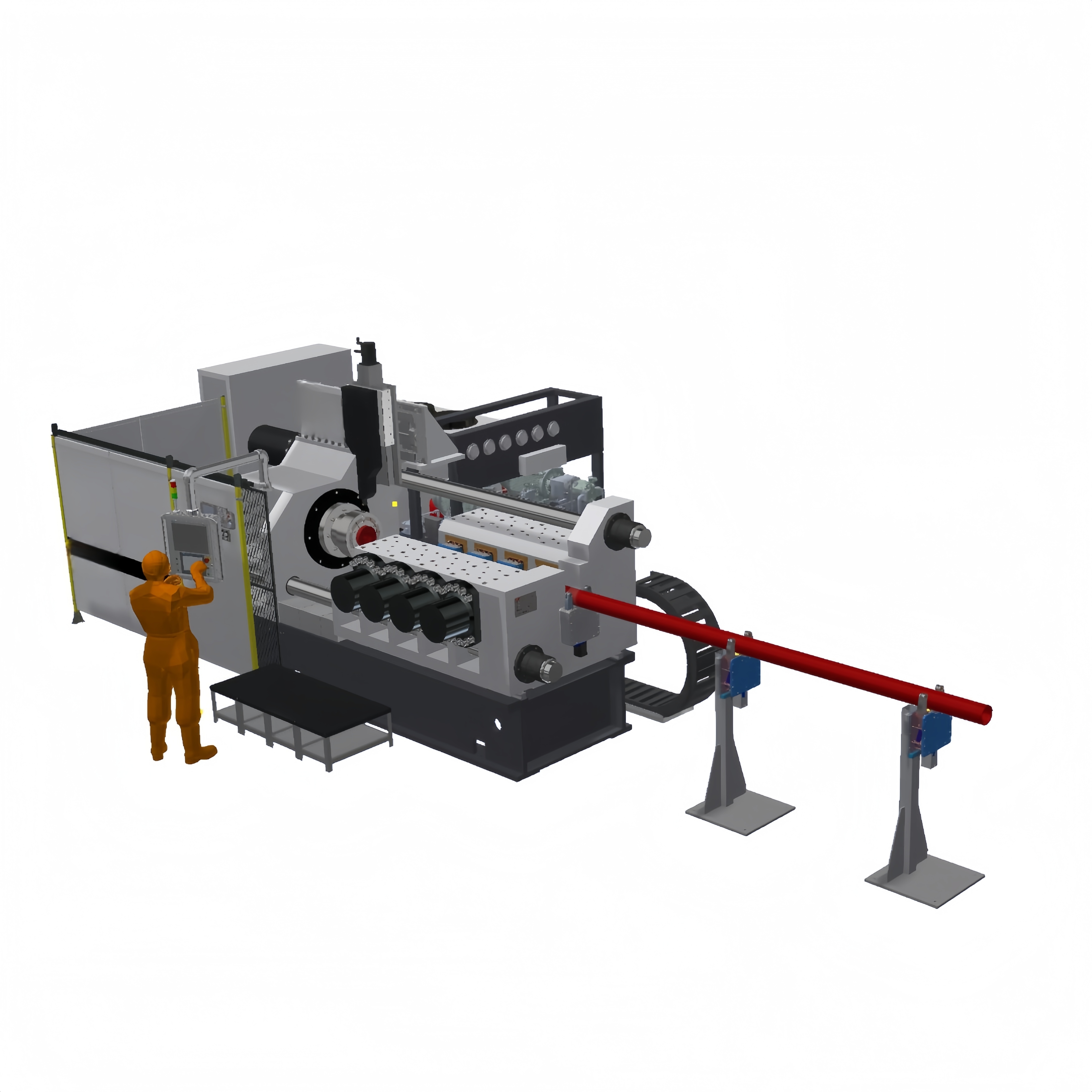

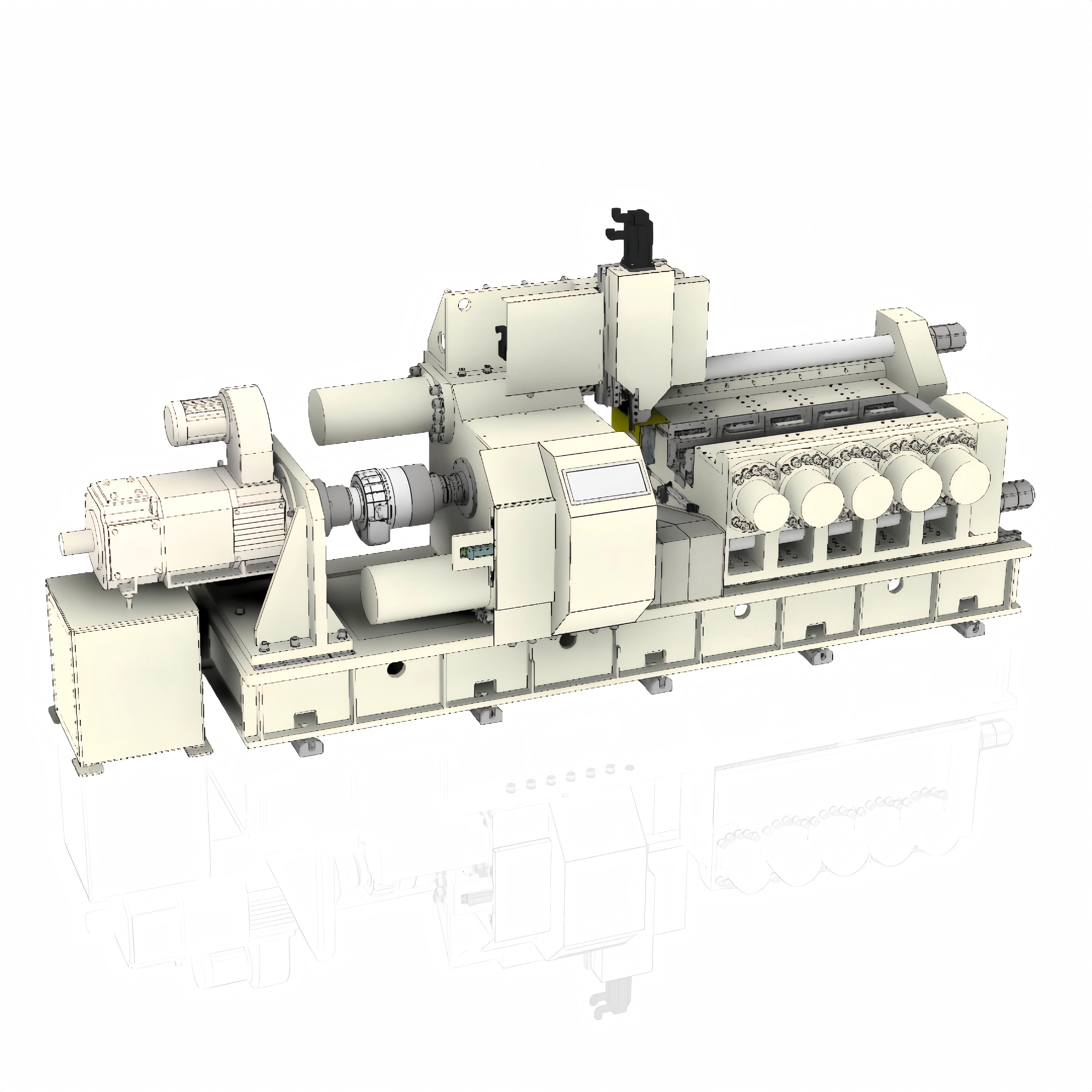

เครื่องเชื่อมด้วยแรงเสียดทานสำหรับเหล็กเส้นเป็นอุปกรณ์พิเศษที่ใช้ในการต่อเหล็กเส้น (rebars) ที่ใช้ในงานก่อสร้าง ซึ่งเป็นทางเลือกที่เหนือกว่าวิธีการดั้งเดิม เช่น การผูกเหล็กเส้นด้วยสายรัด หรือการเชื่อมอาร์กไฟฟ้า กระบวนการเชื่อมด้วยแรงเสียดทานจะสร้างรอยต่อที่มีความแข็งแรงสูงและเนื้อเชื่อมที่สม่ำเสมอ โดยการหมุนเหล็กเส้นชิ้นหนึ่งเข้าหากัน ทำให้เกิดความร้อนที่ทำให้โลหะบริเวณรอยต่ออ่อนตัว จากนั้นใช้แรงกดตามแนวแกนเพื่อทำการเชื่อมต่อเข้าด้วยกัน วิธีการนี้ทำให้ความแข็งแรงของรอยเชื่อมสูงกว่าเหล็กเส้นเดิม ซึ่งมีความสำคัญต่อความสมบูรณ์ของโครงสร้างในอาคาร สะพาน และโครงสร้างพื้นฐาน อีกทั้งต่างจากการเชื่อมแบบอาร์กไฟฟ้าตรงที่ไม่ก่อให้เกิดสะเก็ดเชื่อม ไอระเหย หรือวัสดุสิ้นเปลือง (เช่น อิเล็กโทรด) ช่วยเพิ่มความปลอดภัยในสถานที่ทำงานและลดต้นทุนวัสดุ กระบวนการนี้ยังมีความรวดเร็วกว่า โดยใช้เวลาแต่ละรอบเพียง 10-30 วินาที ส่งผลให้งานก่อสร้างมีประสิทธิภาพมากขึ้น เครื่องเชื่อมด้วยแรงเสียดทานสำหรับเหล็กเส้นของ WondersunM ถูกออกแบบมาเพื่อรองรับขนาดเส้นผ่าศูนย์กลางของเหล็กเส้นที่ใช้ทั่วไป (เช่น 12 มม. ถึง 40 มม.) และเกรดของเหล็กเส้น (เช่น HRB400, HRB500) พร้อมทั้งปรับตั้งค่าพารามิเตอร์ให้เหมาะสมกับประเภทเหล็กต่าง ๆ โครงสร้างแข็งแรงทนทานต่อสภาพแวดล้อมในพื้นที่ก่อสร้าง ในขณะที่ระบบควบคุมแบบดิจิทัลช่วยให้คุณภาพของการเชื่อมมีความสม่ำเสมอ ด้วยการส่งออกไปยังตลาดมากกว่า 100 ประเทศ บริษัทฯ ยังมีบริการฝึกอบรมและสนับสนุนการใช้งานในพื้นที่จริง เพื่อให้มั่นใจว่าเป็นไปตามมาตรฐานการก่อสร้างระดับโลก (เช่น ACI, BS) เครื่องจักรเหล่านี้จึงเป็นตัวเลือกที่เชื่อถือได้สำหรับผู้รับเหมาที่มองหาการเชื่อมต่อเหล็กเส้นที่มีความทนทานและมีประสิทธิภาพ