Accuracy and Precision: How Digital Caliper Performance Compares to Vernier

Resolution, Repeatability, and Real-World Measurement Consistency

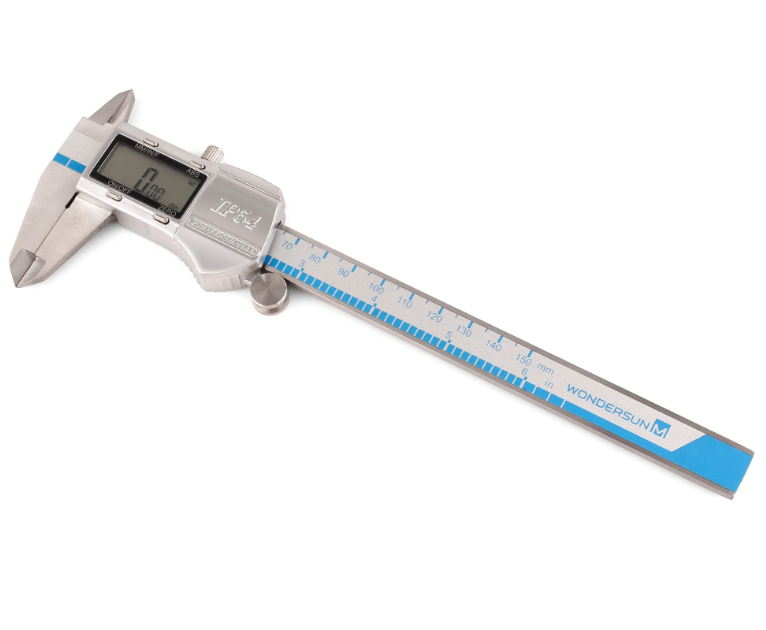

Digital calipers can measure down to 0.01 mm, which is actually double what most vernier calipers manage at their standard 0.02 mm limit. This makes them much better for reducing those annoying rounding errors during important quality checks. When we look at repeatable tests in controlled environments, digital versions consistently hit within plus or minus 0.005 mm. That's pretty impressive compared to traditional vernier tools that only get around plus or minus 0.01 mm accuracy. The problem with old school verniers isn't just about precision though. Their mechanical parts tend to play tricks on readings because of that annoying backlash when sliding components move. Real world experience tells us something else too. Digital calipers keep their accuracy even after making thousands of measurements, sometimes as many as 10,000 cycles. Vernier scales tell a different story though. They start losing accuracy over time as those little gears and pins inside wear down from constant use. Both types deal with thermal expansion issues at about the same rate, roughly 0.001 mm per degree Celsius for stainless steel materials. But here's where digital really shines. Those electronic displays completely remove the parallax problems people often face when trying to read tiny markings on vernier scales.

Environmental and Human Factors: Parallax Error, Thermal Drift, and Operator Dependency

The old school vernier calipers can really mess up measurements because of parallax issues. When someone looks at them from different angles, they might be off by as much as plus or minus 0.03 mm, especially when someone isn't too experienced with these tools. Digital calipers fix this problem completely thanks to their clear LCD screens. Factory tests showed that these digital versions cut down on mistakes made by workers by around 70 percent. Both types still have problems with heat expansion happening at the same rate, but digital ones adjust quicker when temperatures change, which means they stabilize faster during actual work. People need way more practice to get good at reading vernier calipers properly. Training takes about 30% longer compared to digital models before someone becomes proficient enough for real production tasks. Vernier calipers do hold up better in damp conditions though. The electronic parts inside digital calipers tend to fail more often when there's lots of moisture in the air or when condensation builds up. So whether it rains cats and dogs outside or not actually matters quite a bit when deciding which type of caliper to use on the shop floor.

Ease of Use and Readability: Why Digital Caliper Adoption Is Rising Among Professionals

Eliminating Vernier Scale Interpretation Errors and Reducing Cognitive Load

Digital calipers fix what many see as the biggest problem with traditional vernier tools—the need to interpret scales manually. With clear digital displays showing measurements directly, there's no more guessing games about parallax angles or decimal points getting mixed up. The 2023 Industry Skills Report actually found that this reduces mental strain by around 30%, which makes sense when thinking about how much easier it is just to read numbers straight off a screen. Workers don't have to do those annoying conversions from fractions to decimals anymore either. Plus, most modern models come with that handy button that switches between metric and imperial units instantly, saving time on shop floors where both systems are still in common use across different manufacturing sectors.

Onboarding Efficiency: First-Time Success Rates Across Skill Levels

According to a recent 2024 study on tool usability, workers get about 85 percent accurate measurements right away when using digital calipers compared to just 60 percent with old fashioned vernier tools. The digital interfaces are pretty straightforward really, with those handy zero setting buttons and clear screens that show exactly what they mean. Trainees pick things up much quicker these days, getting fully proficient around 40 percent faster than before. Even experienced techs report saving roughly 15 seconds every time they take a measurement. All this makes a big difference in factories where staff turnover is high. When new people can learn how to use equipment quickly, it helps keep production moving smoothly without unnecessary delays.

Durability, Maintenance, and Environmental Suitability in Industrial Settings

Tools used in industrial settings must be able to handle tough conditions without losing accuracy. Digital calipers have some serious durability issues because their internal electronics don't play well with extreme temperatures, high humidity, or exposure to chemicals. These factors can cause problems like broken displays or inaccurate readings. On the other hand, vernier calipers don't have any electronic parts, but they still need regular maintenance. Lubrication becomes essential when working in damp areas or places with harsh chemicals around. Both kinds of calipers deal with physical stresses like vibrations and impacts daily. Many modern digital models come with rubber seals that offer protection against dust and water, usually rated at least IP54. When it comes to maintenance, digital calipers require changing batteries every so often and keeping them dry to avoid damage. Vernier calipers need checking the scales regularly and making sure all moving parts stay properly lubricated. Foundries and chemical processing facilities often rely on vernier calipers since they work reliably even when temperatures swing wildly. Digital calipers make more sense in controlled factory environments where quick measurement data is worth the extra effort to maintain proper storage conditions. Getting this right matters a lot financially too. According to a study by Ponemon Institute from last year, plant failures caused by using the wrong tools for the environment cost companies about $740,000 each year. That's why matching tool capabilities to specific workplace hazards remains such a critical decision point for shop managers.

Total Cost of Ownership and Smart Selection Criteria by Application

5-Year TCO Analysis: Battery Life, Calibration Stability, and Repair Costs

When considering whether to buy calipers, people tend to focus first on what they pay upfront. But if we look at things over about five years, there's actually quite a bit more involved with digital models. These gadgets need batteries replaced somewhere between $10 and $40 each year, plus regular calibration checks that can run anywhere from $80 to $150 annually. And let's not forget about possible repairs down the road. Digital calipers really struggle when used nonstop because they rely entirely on batteries, unlike traditional vernier calipers that work without any external power source at all. What many don't realize is how much temperature changes affect their accuracy too. Digital versions start drifting off track much quicker in hot or cold environments, which means technicians end up recalibrating them roughly 30% more often compared to old fashioned ones. When it comes time for fixes, the math gets even worse. Replacing a broken screen on a digital model eats up around two thirds of what someone originally paid for it, whereas getting a vernier caliper fixed usually only costs about one fifth of its purchase price. That said, some specialized labs still prefer digital options since they offer faster measurements and connect easily to computers for data tracking. However, most workshops dealing with extreme temperatures, dust buildup, or chemical exposure find that good old vernier calipers stand the test of time better both financially and functionally.

Table of Contents

- Accuracy and Precision: How Digital Caliper Performance Compares to Vernier

- Ease of Use and Readability: Why Digital Caliper Adoption Is Rising Among Professionals

- Durability, Maintenance, and Environmental Suitability in Industrial Settings

- Total Cost of Ownership and Smart Selection Criteria by Application