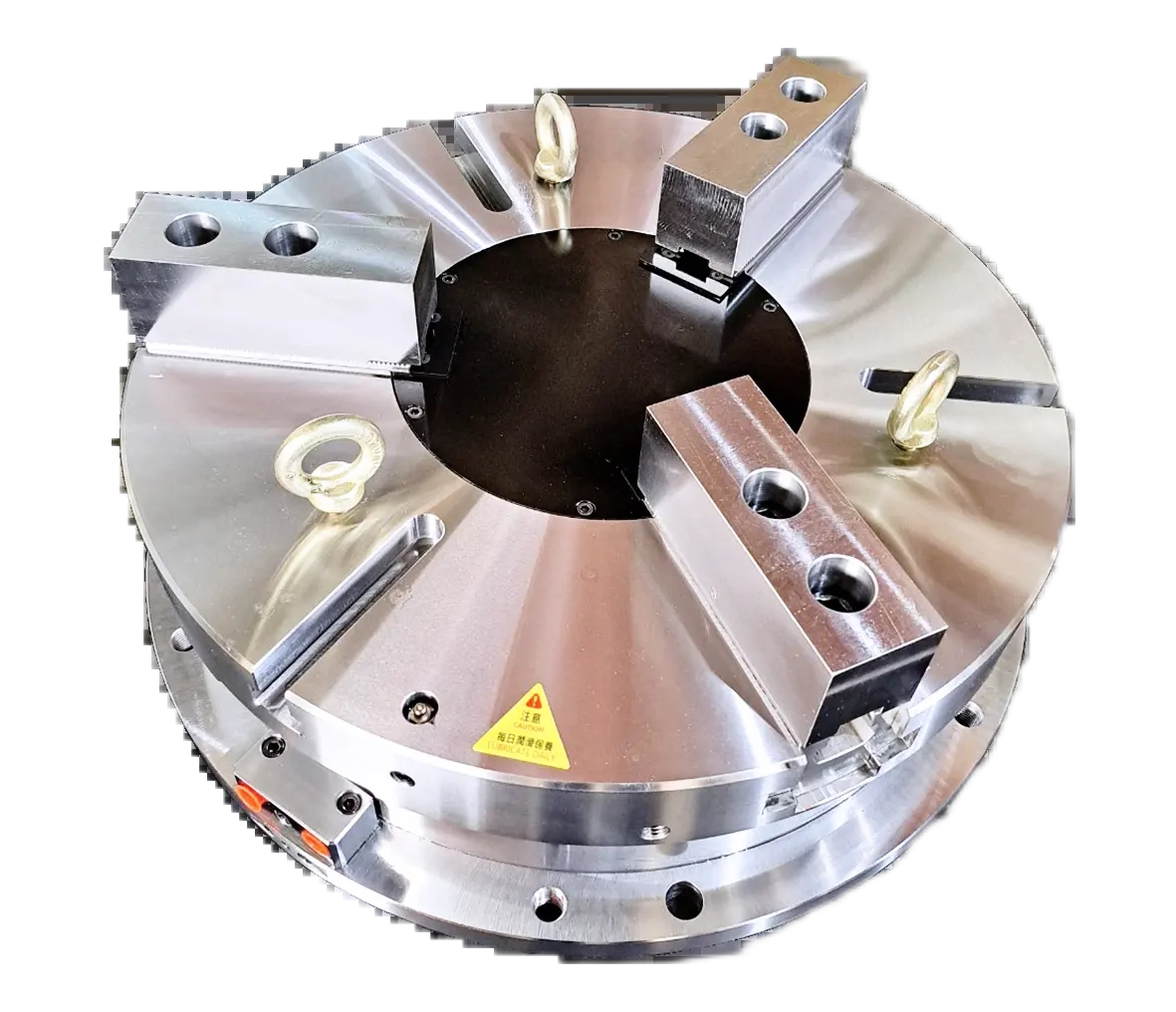

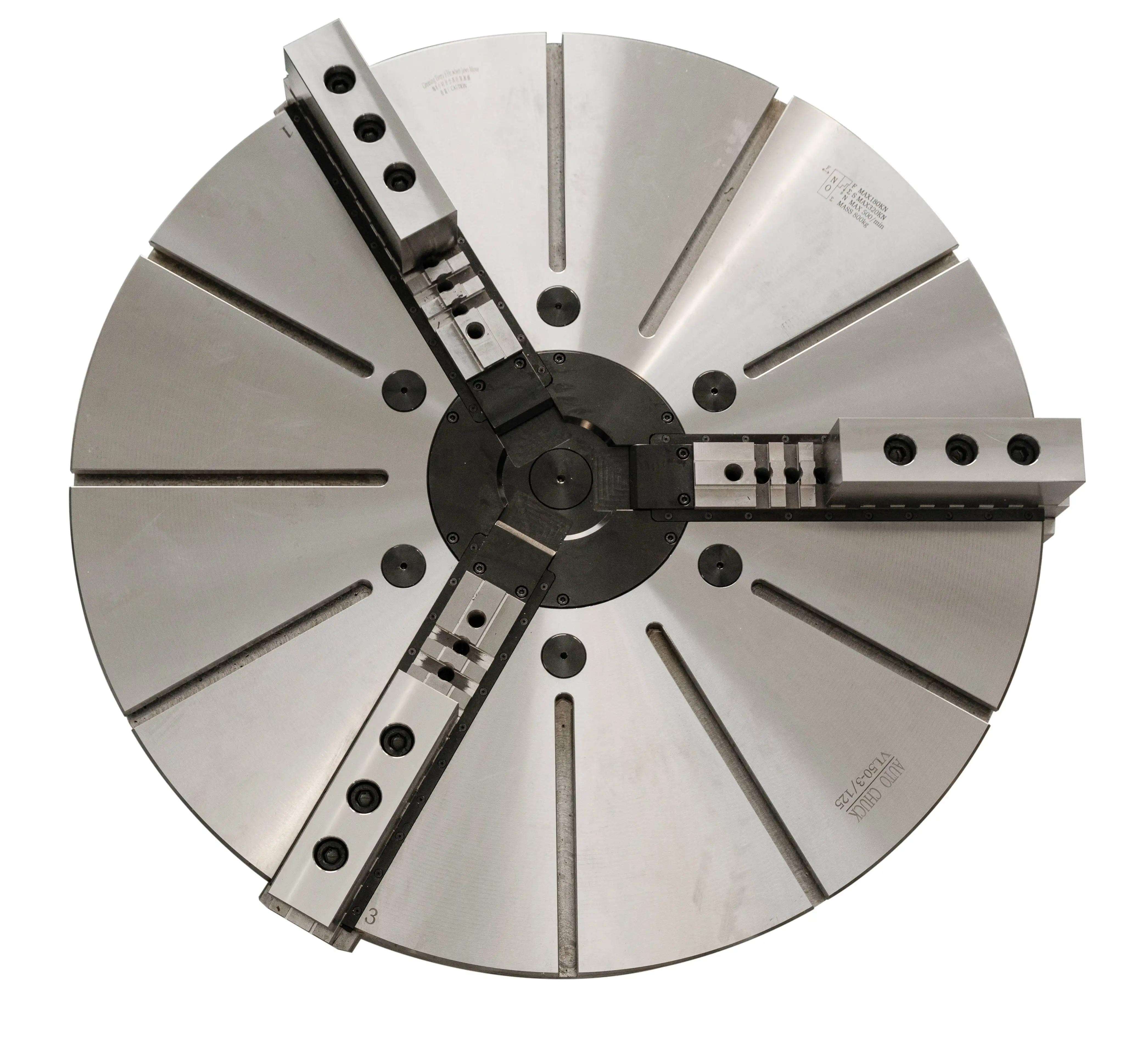

As with other industries, construction has also greatly benefited from the use of CNC technology. The accuracy, ease of use, and repeatability in connection with their speed all follow the basic requirements set for modern equipment. Verifiably surpassing ISO 2768-1 standards on geometric tolerances would mean Vero has quite a reputation for screw type lathes. It can be sightsed in Vero's patented кич and фня програм, boasting screw on jaws that allow less than 0.001 mm runs and back lashes below 0.003 mm to attest the claims. That TIR stands for True Interchangeable Relationship constructs the chuck's body out of special temperature compensating materials with claimed thermal expansion behavior of 11x10⁻⁶/°C.