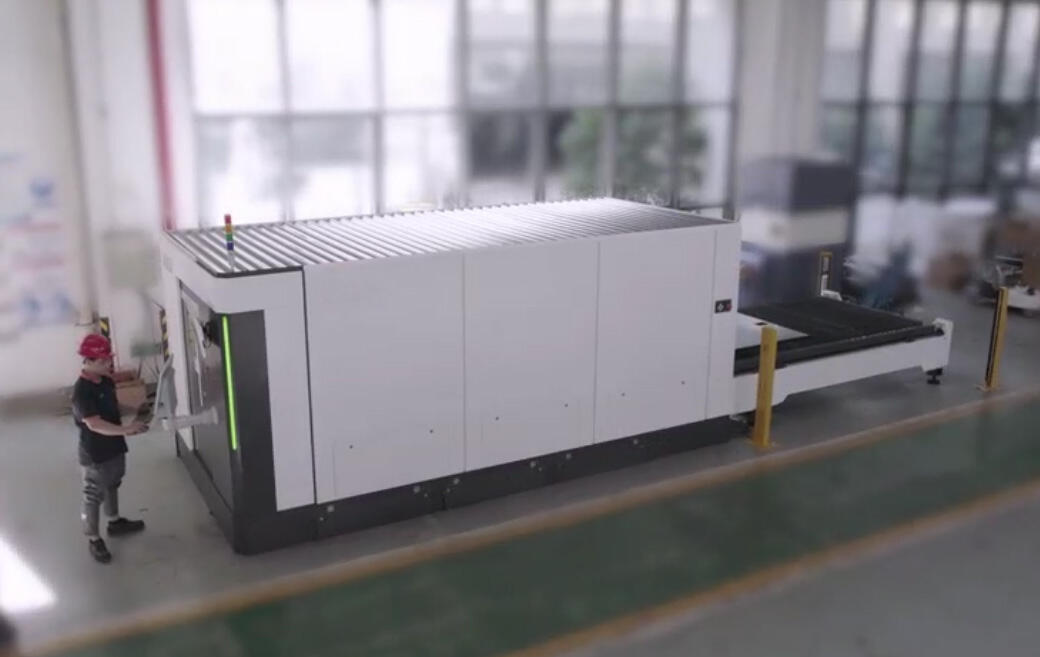

Innovations in Laser Cutting Machines for Modern Industries

The last few years have seen a major boost in the manufacturing industry with the introduction of precise laser cutting technologies. In today’s article, I’ll be outlining the history of laser cutting machines and their significance to co...

View More