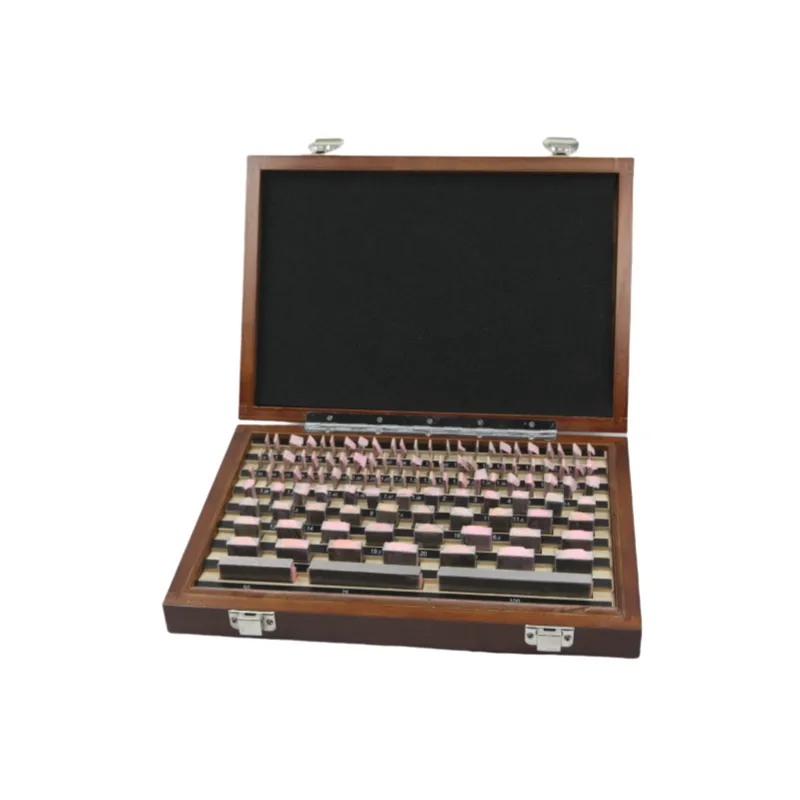

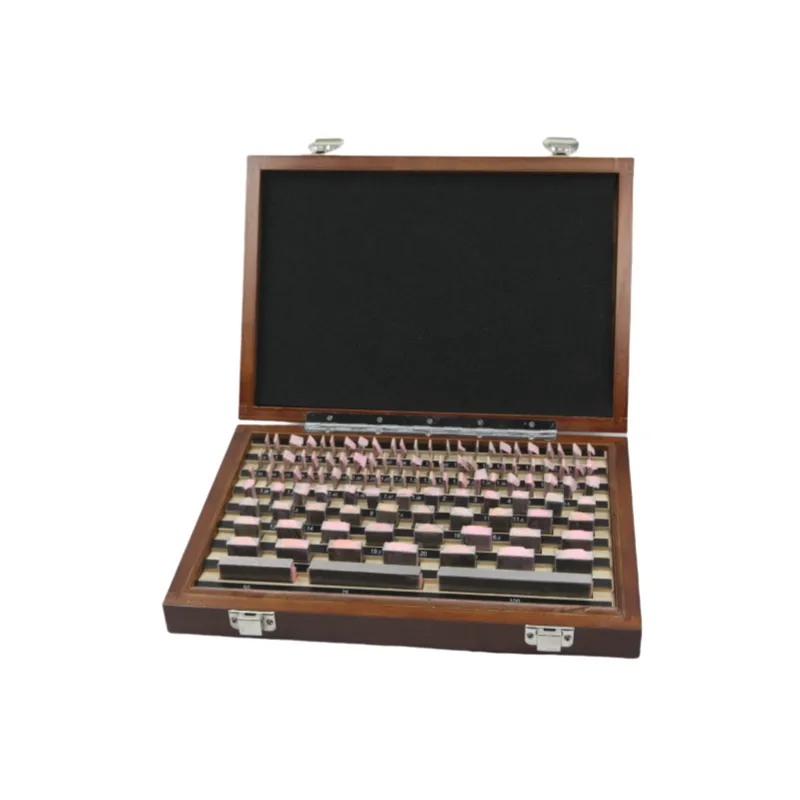

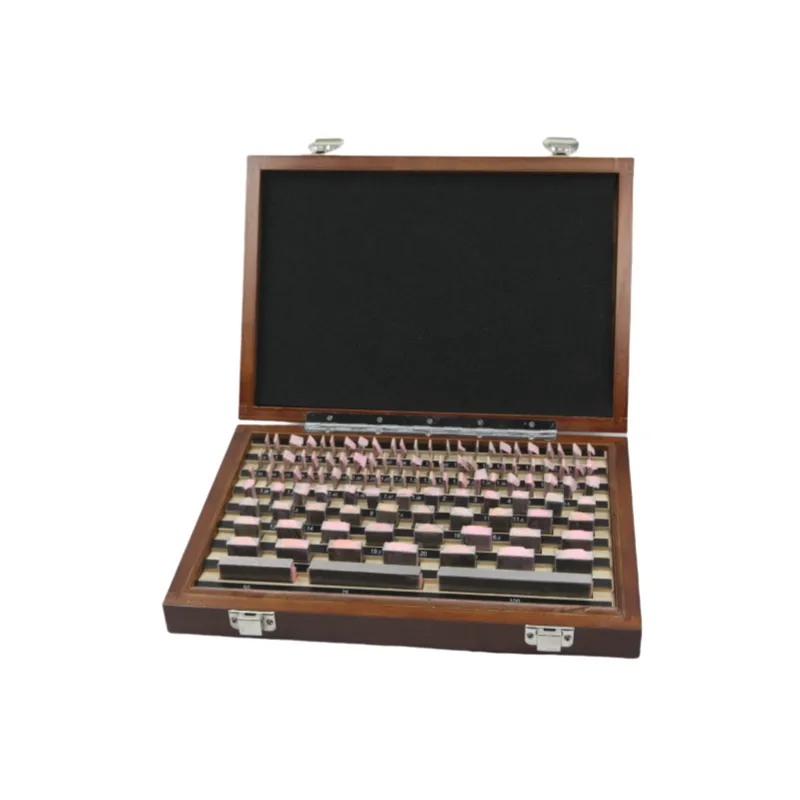

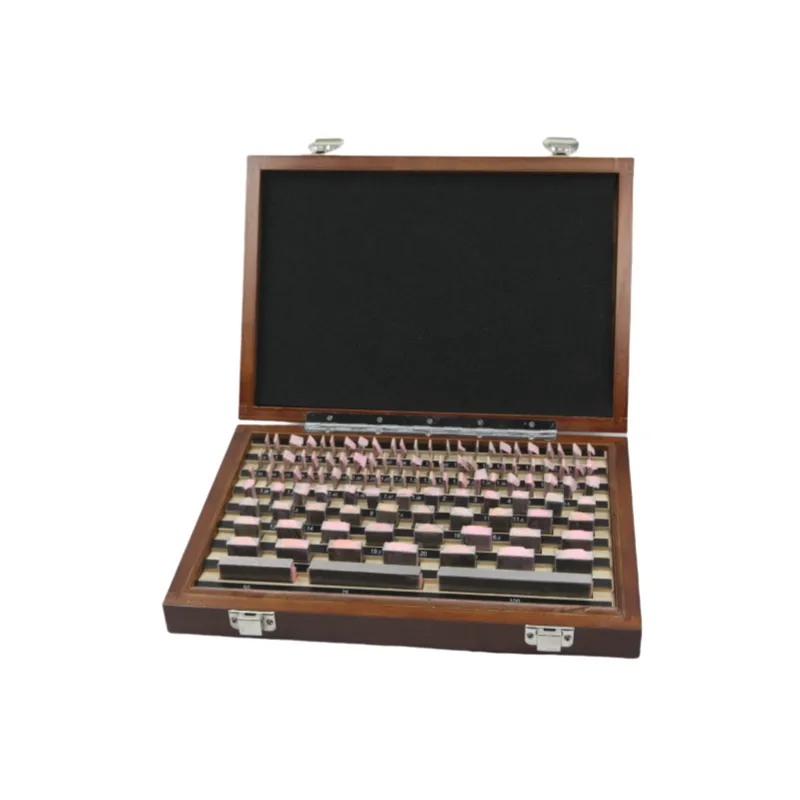

If you compare the hardness of carbide gauge blocks, which is 1300HV, to that of steel, it is easy to see it is much higher. Therefore, unlike steel, carbide works best in harsh environments such as plating baths or foundries. Tungsten carbide does not have a high thermal expansion coefficient making it better than steel. Its coefficient is 4.5 × 10^{-6} /°C. Because of this, better calibration if air gauges and plug gauges is attainable, straigth with their ultra-flat surfaces, which have a flatness of \leq 0.0002 mm. Carbide gauge blocks conform with ISO 10360-2 with metrology regarding space.