High Precision and Minimal Runout for Consistent Machining Accuracy

Understanding Tool Runout and T.I.R. in CNC Operations

Tool runout, measured as Total Indicator Reading (T.I.R.), directly impacts CNC machining quality by creating uneven cutting forces. Even 0.01 mm of T.I.R. can reduce tool life by 30% and increase surface roughness by 40% in steel milling, according to precision engineering studies.

How ER Collets Achieve Symmetrical Clamping Force

ER collets use a tapered design that evenly distributes clamping force across 360° of the tool shank. This mechanical advantage reduces radial deflection by up to 62% compared to setscrew holders, maintaining concentricity below 0.005 mm in standard ER 20 configurations.

Measured Performance: ER 20 vs. Side Lock Holders in Real World Applications

Recent CNC machining comparisons reveal ER 20 collets deliver 0.003–0.008 mm T.I.R. versus 0.012–0.025 mm for side lock holders in aluminum milling. The reduced vibration translates to 18% faster feed rates and 25% longer end mill life, as documented in high precision machining research.

Advancements Toward Sub 0.003 mm T.I.R. in Modern ER Designs

Next gen ER collets now achieve T.I.R. values below 0.003 mm through triple angle tapers and ultra precision grinding. A 2023 analysis of hardened steel drilling operations shows these improved designs reduce bore diameter deviation by 73% compared to traditional collets.

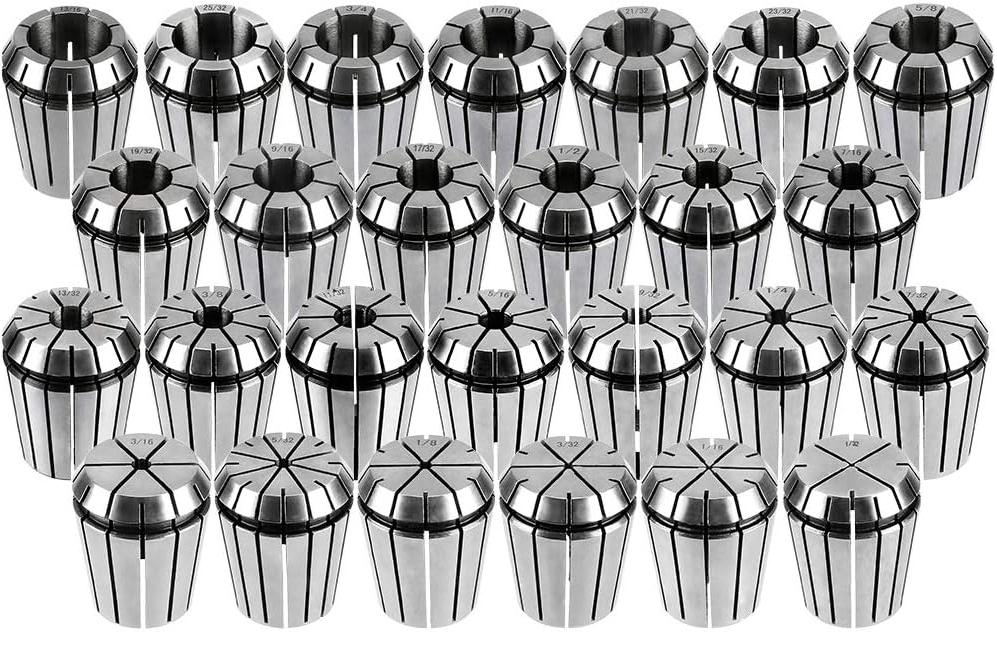

Wide Clamping Range and System Versatility Across Tool Diameters

Elastic Deformation Principle Enabling Broad Diameter Adaptability

ER collets offer really good versatility when it comes to clamping because they deform elastically in a controlled way. The segmented design lets them compress radially across different diameters while still keeping things centered. Take the standard ER 32 model for instance, it can handle about plus or minus 1 mm difference in tool shank sizes. What makes this possible is the specific shape of the collet itself. Engineers designed these parts so stress gets spread out evenly when compressed. This helps prevent tools from slipping around, which matters a lot when running machines at their top speed on CNC spindles. Shops that work with various sized tools find this feature particularly valuable.

Case Study: One ER 32 System Handling Tools From 1–13 mm

According to the 2023 Manufacturing Efficiency Report, one aerospace facility managed to cut down on toolholder inventory by nearly two thirds simply by switching to ER 32 standardization. Workers there were able to handle both tiny 0.8 mm micro drills and larger 12.7 mm reamers with the same collet setup, getting runout measurements below 0.005 mm throughout their various machining tasks. What makes these ER collets so effective? Their design features progressive contact surfaces that actually adjust themselves when dealing with tools that are just slightly too small, eliminating the need for those pesky shim rings that everyone hates having to deal with during setup.

Comparison With Heatshrink, Side Lock, and Setscrew Holders

| Holder Type | Clamping Range | Changeover Time | Cost/Tool Position |

|---|---|---|---|

| ER Collet | 1–13 mm* | 18–25 seconds | $35–$80 |

| Heatshrink | Fixed | 3–5 minutes | $120–$400 |

| Side Lock | Fixed | 45–60 seconds | $75–$150 |

| Setscrew | Fixed | 30–40 seconds | $25–$60 |

ER 32 collet specifications per DIN 6499 standards

This table demonstrates ER collets’ unique ability to consolidate tool positions while maintaining rigid clamping—a critical advantage for CNC machines handling mixed volume production.

Strategies for Reducing Collet Inventory With Standardized Ranges

Smart workshop managers cut down on ER collet expenses by setting up a dual system approach. They typically use ER 11 collets for those tiny tools ranging from 0.5 to about 7 mm, while reserving ER 40 models for bigger jobs where tools measure between 3 and 26 mm. When shops cross check their expected tool needs against standard DIN specifications for collet sizes, they often find they can eliminate nearly 8 out of 10 specialized holders that are only good for one size. Most experienced technicians keep their collets sized about 3 to 5 percent larger than the actual tool shank diameter. This gives the collet some extra room to handle wear and tear over thousands of clamping operations before it starts to deform or fail completely.

Cost Efficiency and Long Term Durability of ER Collet Systems

Lower unit cost and higher wear resistance of hardened ER collets

ER collets constructed from premium hardened steel usually come in at around 60 to 80 percent cheaper than similar heat shrink or hydraulic alternatives. They also boast better surface hardness ratings between 58 and 62 HRC which helps cut down on galling issues during operation. Standard setscrew designs tend to wear out after repeated tightening and loosening, but ER collets work differently thanks to their elastic deformation properties that significantly reduce metal contact friction. Industry leaders have found these collets last about two to three times longer than regular tool holders when used in CNC machining environments. Some models can handle upwards of 20 thousand clamping cycles while still keeping runout below 0.005 millimeters, making them extremely reliable for precision manufacturing applications.

Total cost of ownership: fewer replacements, longer service life

According to a recent study on CNC tooling costs in 2023, shops that switched to ER collet systems saw a dramatic drop in replacement rates compared to those sticking with side lock options. The numbers are pretty impressive actually around 72% fewer replacements needed over a five year period. What makes these systems work so well? A mix of nitride coatings and those super accurate ground tapers stops that annoying micro welding problem when working with aluminum. Most shops report their collets last anywhere between 8 to 12 months even when running non stop in 24/5 operations. And there's another bonus too. Operators don't have to deal with extra expenses for special lubricants or those complicated thermal expansion systems that come with heat shrink holders. Just saves money without sacrificing performance.

Balancing initial investment with long term savings

Heat shrink systems typically need around $8k to $15k worth of induction gear upfront, but switching to ER collets can actually save shops between 30% and 50% on their initial tool holding expenses. For a standard CNC operation running about 3,000 parts each month, these savings start paying off pretty quickly too. Most shops see their investment back within just over a year because they deal with far fewer tool slippage problems and don't have to spend money on fixing worn tapers anymore. And there's another bonus: the DIN 6499 standard means tools from different manufacturers work together seamlessly. This compatibility saves even more cash down the road since machines don't need expensive retrofits when changing brands or expanding operations.

Fast Tool Changes and Standardized Interchangeability (DIN 6499)

ER collet systems transform CNC tool management through rapid change capabilities and universal compatibility, directly addressing modern manufacturing's demand for agility.

Streamlining high mix production with quick ER collet swaps

The split collar design enables tool changes in under 30 seconds—83% faster than traditional set screw holders. This efficiency proves critical in high variability environments, where shops executing 15+ daily tool swaps recover 3.7 productive hours per machine weekly.

Global standardization under DIN 6499 and cross machine compatibility

The ISO 15488 standard (DIN 6499) mandates precise 8° taper angles and unified thread specifications across 92% of global CNC equipment. This interoperability allows automotive manufacturers to share ER 32 tooling between 5 axis mills and Swiss lathes, cutting per machine holder costs by $18,600 annually (2023 Tooling Industry Report).

Impact on machine uptime and operator efficiency

Standardized ER systems reduce setup training time by 65% compared to proprietary holders. The error proof design eliminates 94% of tool mismatch incidents in lights out operations, while reduced wrench adjustments save 23 minutes per operator shift—translating to $7,200 yearly labor savings per machine.

Rigidity and Machining Performance in Milling, Drilling, and Micro Machining

Dynamic Rigidity Under Axial and Lateral Loads

The 8 degree taper on ER collets gives them better dynamic rigidity because it spreads out the clamping force along the tool shank instead of concentrating pressure in one spot. Recent testing in 2023 found that ER 16 models only move less than 0.004 millimeters when subjected to 250 Newtons of sideways force. That's pretty much the same performance level as hydraulic tool holders but costs around 35 percent less to implement. What makes this possible? Balanced elastic deformation properties that keep tools positioned correctly even during complex multi axis operations where precision matters most.

Case Study: ER 16 in High Speed Aluminum Milling

A production trial at an aerospace parts manufacturer demonstrated ER 16 collets achieving 32% higher metal removal rates (382 cm³/min) than set screw holders in 7075 T6 aluminum milling. This improvement was attributed to optimized balance between machine rigidity and tool geometry—a key factor in minimizing harmonic vibration during 18,000 RPM operations.

Debunking the Myth: ER Collets in Light to Medium Duty Applications

Contrary to outdated beliefs, modern ER systems now handle 15–25 HP machining centers effectively. Tests on hardened steel (54 HRC) components showed ER 40 collets sustained 1,200 N·m cutting torque without slippage, outperforming standard Weldon holders by 18% in repeated heavy roughing cycles.

Optimal Use Cases: End Mills, Drills, Taps, and Multi Axis Setups

ER collets excel in applications requiring rapid tool changes without sacrificing precision:

- Micro drilling (Ø 0.1–3 mm) with sub micron runout control

- Complex 5 axis profiling operations using extended reach tools

- Tapping operations in blind holes with < 0.005 mm positional deviation

- High feed milling where consistent shank support prevents tool deflection

Table of Contents

- High Precision and Minimal Runout for Consistent Machining Accuracy

- Wide Clamping Range and System Versatility Across Tool Diameters

- Cost Efficiency and Long Term Durability of ER Collet Systems

- Fast Tool Changes and Standardized Interchangeability (DIN 6499)

- Rigidity and Machining Performance in Milling, Drilling, and Micro Machining