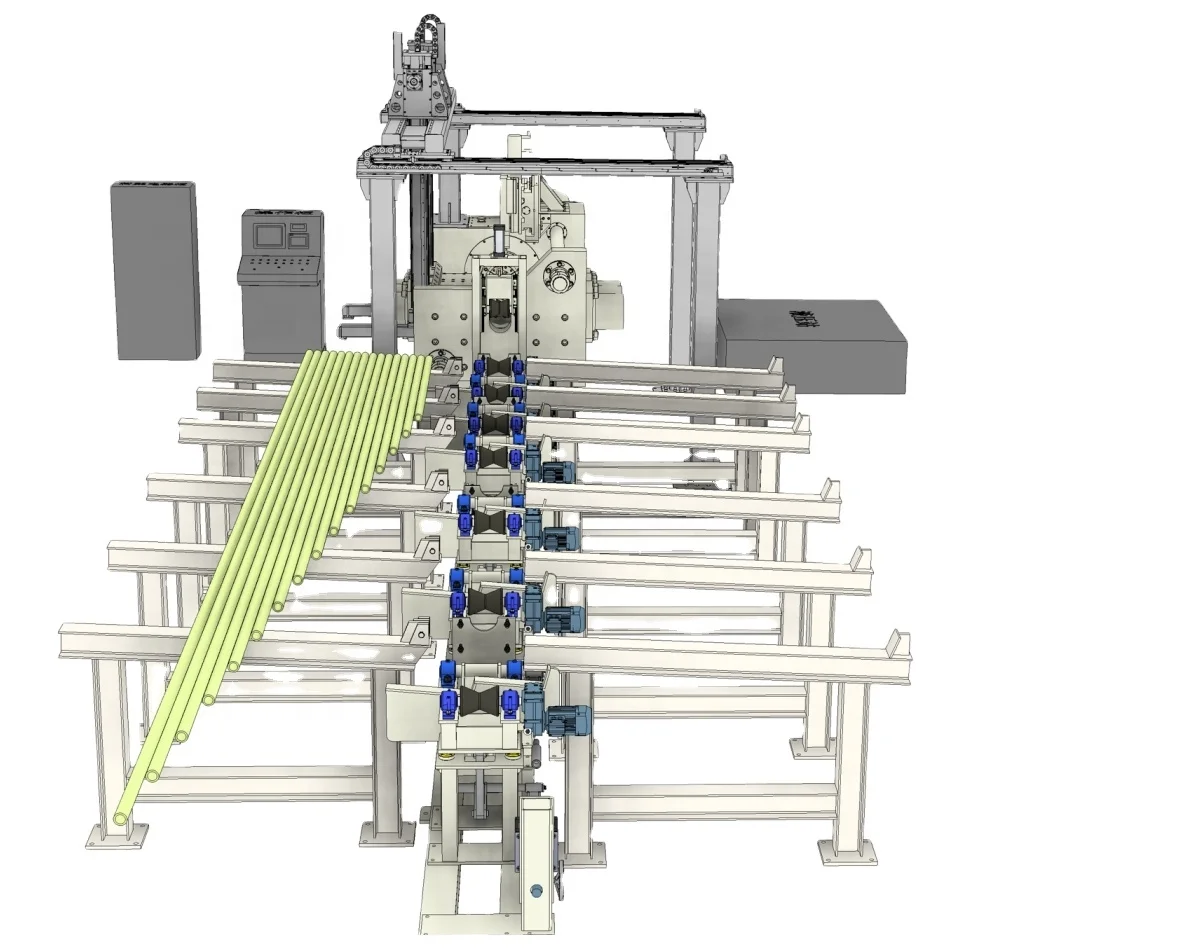

Hydraulic Cylinder Thrust Rod friction welding machine

Hydraulic Cylinder Thrust Rod friction welding machine

The Friction Welding Process

BEFORE WELDING

Parts are mounted in the Friction Welder

Rotating Part is spun up to speed of 1,000 RPM.

PHASE 1 (FIRST FRICTION)

Parts are rubbing together, at low force, to accomplish a clean-up of the two surfaces and initialize generation of heat.The force applied during First Friction is -30% of the Second Friction.

PHASE 2 (SECOND FRICTION)

The increased pressure brought about during second friction causes the metal to become “plastic” and flows outward from center to form the characteristic “Flash”.

Once the designed Flash is accomplished, the rotation is rapidly stopped. The Process then moves to the Forge Phase.

PHASE 3 (FORGE)

The Forge is caused by the application of the highest of the three process pressures. The forge phase takes place while the components are at a complete stop.

The pressure is maintained until the weld joint is sufficiently cooled.

This step promotes refinement of the microstructure of the weld.

FLASH REMOVAL

The flash is removed (if desired) by conventional machining practices. Removal of the Weld Flash is optional.

Application:

• joining materials with various physical properties

• joining elements with various shapes and dimensions

• joining dissimilar materials using an intermediate insert made of a material that can be easily welded to

both elements being connected

• joining bars or pipes that replace machined metallic elements of structures – reduction of material

consumption

• joining structural elements, previously made of expensive metals, with bimetallic elements consisting of

cheaper metals or metals that are more suitable for practical reasons – cost reduction

• joining several elements of simple shapes (easy to manufacture) that replace complex forgings or castings

– cost reduction

• joining elements in serial production – replacement of less efficient welding methods

| Model | Max.upset force(KN) | Max.welding area(mm) | Welding dia. | Speed(rpm) |

| DBS-2 | 20 | 20-140 | 5-13 | 5000 |

| DBS-5 | 50 | 50-260 | 8-18 | 3000 |

| DBS-12 | 120 | 150-700 | 14-30 | 1500 |

| DBS-20 | 200 | 150-1020 | 14-36 | 1500 |

| DBS-30 | 300 | 314-1600 | 20-45 | 1200 |

| DBS-40 | 400 | 500-2400 | 25-55 | 1100 |

| DBS-63 | 630 | 960-3400 | 35-64 | 1000 |

| DBS-80 | 800 | 1300-5000 | 40-75 | 950 |

| DBS-100 | 1000 | 1600-6000 | 45-86 | 890 |

| DBS-125 | 1250 | 2000-7800 | 50-100 | 600 |

| DBS-160 | 1600 | 4300-8792 | 89-160 | 580 |

| DBS-200 | 2000 | 5100-12500 | 102-189 | 500 |

| DBS-250 | 2500 | 3850-15500 | 70-140 | 500 |

| DBS-320 | 3200 | 6400-20000 | 90-160 | 380 |

| DBS-400 | 4000 | 8000-25000 | 100-180 | 350 |

| DBS-500 | 5000 | 8000-31400 | 100-200 | 320 |

| DBS-700 | 7000 | 8000-44000 | 100-240 | 320 |

WHY CHOOSE BLUESTAR BRAND MACHINE TOOLS:

1) High quality with competitive price

2) More than 10 years export experience

3) CE,SGS, ISO Certificated

4) OEM SERVICE AVAILABLE

5) 24 HOURS’ ONLINE SERVICE FOR PROBLEM SHOOTING (SKYPE,Trademanager)

6) 12 months quality warranty

High Precision Monoblock Vernier Caliper Made of Hardened Stainless Steel 0-200mm/0-8inch

0-150mm 6 Inch Digital Caliper Vernier Price

cylindrical centering mounting soft jaws k10 series number of two jaws self centering lathe chuck

Friction Welding Machine Friction Welder Automatic Friction Welding Machine